Fryer Oil Filter Sysytem

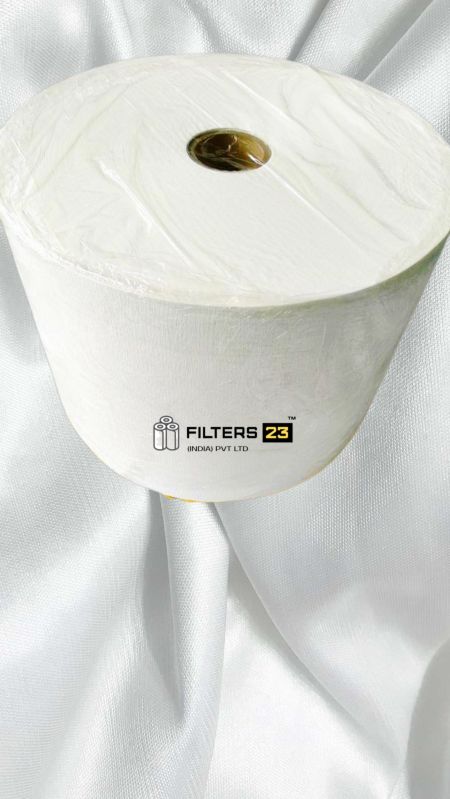

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Cooking Oil Filter Paper Roll, Filter Sheets FOR Fryer Oil Filter, Food Oil Filter Paper Roll, FRYER OIL FILTER BAGS, Fryer Oil Filter Machine, FRYER OIL FILTER SYSTEM FRY-FC-50/30, FRYER OIL FILTER SYSTEM FRY-US-20/55, FRYER OIL FILTRATION FRY-EU-40, Frying Oil Filter Paper Roll, Frymaster Fryer Filter Bags, Heny Peny Fryer Filter Bags, Oil Filter Bag, Pitco Fryer Filter Bag and S.s Fryer Oil Filter System from Mulchand.

| Business Type | Manufacturer, Exporter |

| Brand | Filters23 India Pvt Ltd |

| Country of Origin | India |

| Type | Filter Roll, Cooking Oil Filter Paper |

| Pattern | Plain |

| Feature | Eco Friendly |

| Certification | CE Certified, ISO 9001:2008 |

| Color | White |

| Material | Viscos |

| Warranty | 1 year |

| Port | SANAD |

| Payment Terms | L/C, D/A |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | roll, bundle , boxes |

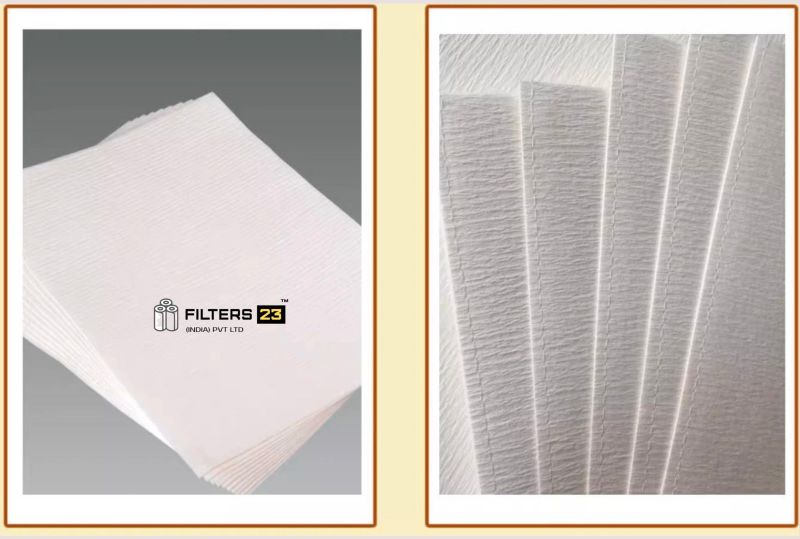

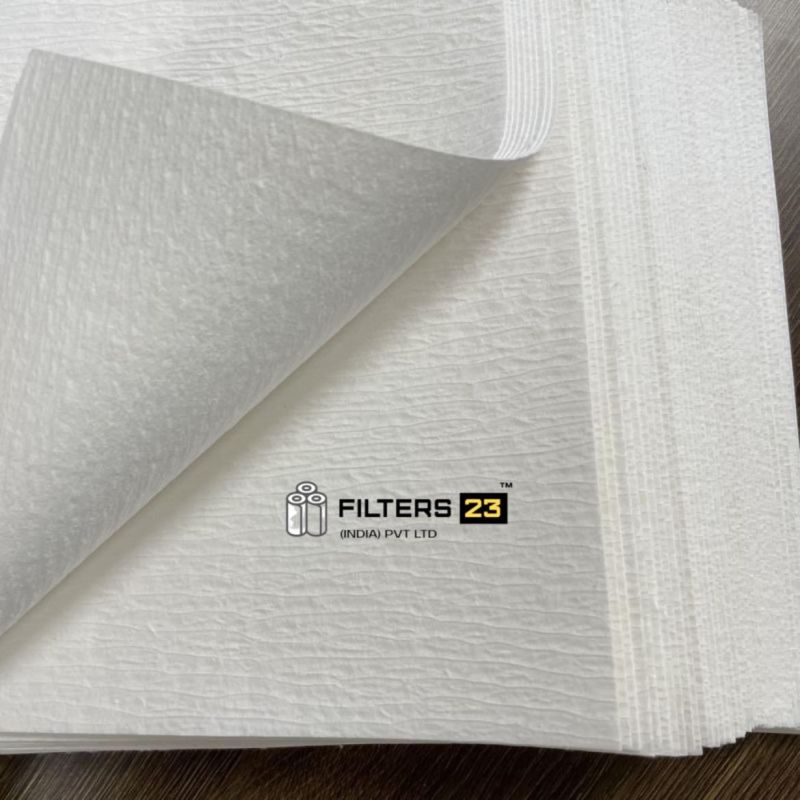

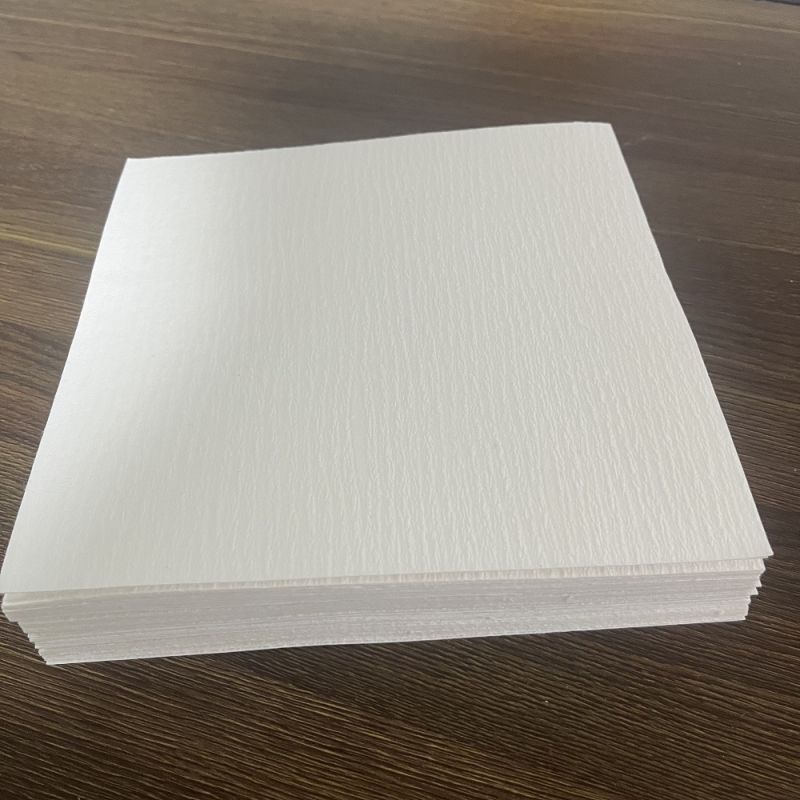

Cooking oil filter paper, also known as deep fryer filter paper or oil filtration paper, is a specialized type of filter paper used in the foodservice industry and commercial kitchens for filtering and purifying cooking oil. The primary purpose of cooking oil filter paper is to remove impurities, debris, and food particles from used frying oil, extending its lifespan and ensuring the quality of fried foods. Here's how it works and some key features:

Material: Cooking oil filter paper is typically made from viscose fibers or a combination of cellulose and synthetic materials. These materials are chosen for their ability to capture and retain particles while maintaining food safety standards.

Filtration: When hot cooking oil is passed through the filter paper, it traps and retains suspended solids, crumbs, and other contaminants. This process helps clarify the oil, resulting in cleaner and better-tasting fried foods.

Mesh Size: Cooking oil filter paper comes in various mesh sizes, which determine the level of filtration. Finer mesh sizes can capture smaller particles but may require more frequent replacement as they become clogged with debris.

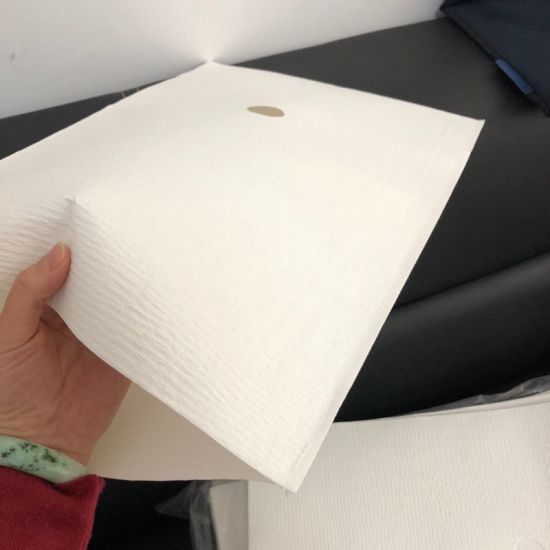

| Business Type | Manufacturer, Exporter |

| Feature | COOKING OIL FILTRATION |

| Brand Name | FILTER SHEET,FILTERS23 INDIA PVT LTD |

| Material | Food Oil Filter Paper |

| Color | White |

| Condition | New |

| Type | COOKING OIL FILTER SHEET |

| Warranty | 1 Year |

| Country of Origin | India |

| Port | SANAD |

| Payment Terms | Other |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | BOX PACKING |

We are a leading manufacturer of premium fryer oil filter sheets and filtration systems tailored specifically for the food and beverage industry. Our products are designed to enhance cooking oil longevity, improve food quality, and optimise operational efficiency.

What We Offer:

High-Performance Filter Sheets: Our filter sheets effectively remove impurities from cooking oil, extending its lifespan and improving overall food taste and quality.

Customizable Solutions: We provide various sizes and specifications to fit your unique needs.

Reliable and Durable Materials: Engineered with durability in mind, our sheets withstand high temperatures and repeated use, making them ideal for continuous, commercial-grade filtration.

Cost Savings: Our sheets are designed for durability, allowing for fewer replacements and cost savings over time.

We understand that Frymaster, Pitco, and Filter King are industry leaders in fryer oil filtration, and we have developed customised filter sheets and provide to their customer for best performance of systems. Our filter sheets are crafted to fit seamlessly into all kind of filter machines, optimising the filtration process for longer oil life and improved food quality.

If you're interested, I’d be happy to send samples or discuss further customization options. Please feel free to reply to this email or reach out directly at [ info@ / filters23india@ ].

Thank you for your time, and I look forward to the opportunity to support your filtration needs.

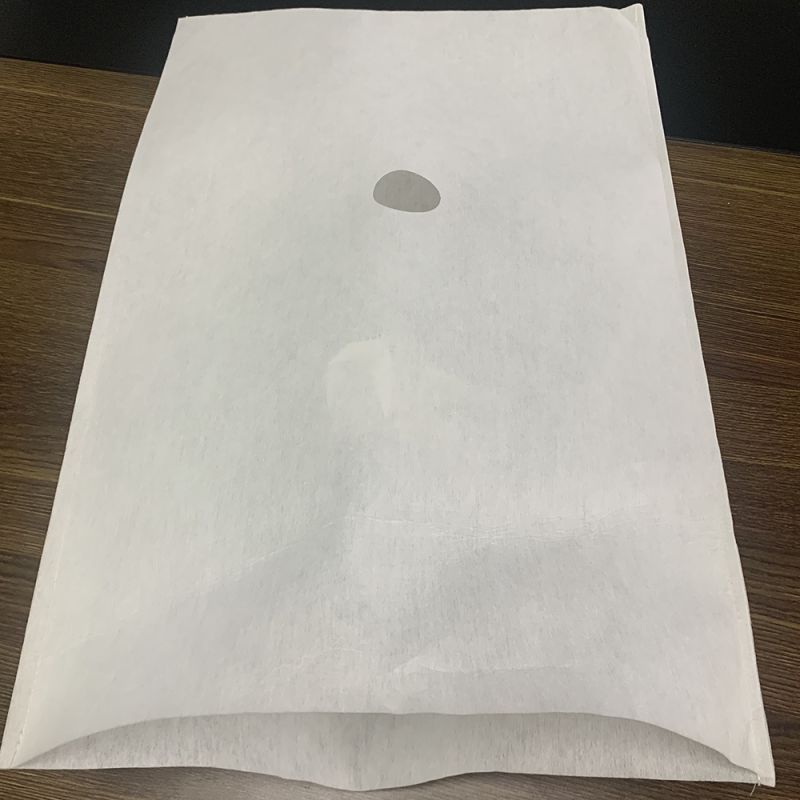

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | filter23 india pvt ltd,filters23 India pvt ltd |

| Material | food oil filter paper |

| Color | White |

| Condition | New |

| Certification | ISO 9001:2008 |

| Packaging Type | bundles |

| Type | oil filter paper roll |

| Country of Origin | India |

| Size | customized |

| Port | SANAD |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | bundles |

Regularly filtering and maintaining frying oil is essential for ensuring the consistent quality of fried foods and avoiding the build-up of burnt residues. Commercial establishments often have dedicated filtration equipment for this purpose, while home cooks can use smaller, disposable filter papers or filter cones when needed.

Filtration: When hot cooking oil is passed through the filter paper, it traps and retains suspended solids, crumbs, and other contaminants. This process helps clarify the oil, resulting in cleaner and better-tasting fried foods.

Disposable: Most cooking oil filter papers are designed for one-time use. After filtration, the used filter paper is typically discarded along with the trapped impurities.

Safety: Cooking oil filter paper is designed to be food-safe and heat-resistant to withstand the high temperatures of frying oil without degrading or releasing harmful substances.

Benefits: Using cooking oil filter paper can help improve the taste and quality of fried foods by removing off-flavours and extending the life of the cooking oil. It can also reduce oil consumption, resulting in cost savings for commercial kitchens.

Cooking oil filter paper, also known as deep fryer filter paper or oil filtration paper, is a specialized type of filter paper used in the foodservice industry and commercial kitchens for filtering and purifying cooking oil. The primary purpose of cooking oil filter paper is to remove impurities, debris, and food particles from used frying oil, extending its lifespan and ensuring the quality of fried foods.

Roll available in below standard sizes & range

| Business Type | Manufacturer, Exporter |

| Brand Name | FILTERS23,FILTERS23,FILTERS23 INDIA PVT LTD |

| Material | Wood Pulp,WOOD PULP |

| Shape | Rectangular |

| Color | White |

| Condition | New |

| Application | COOKING OIL FILTER |

| Operating Temperature | MAX 200 |

| Packaging Type | Carton Box |

| Working Pressure | FRYER OIL FILTER |

| Specialities | Ease Of Install,High Quality |

| Type | FRYER OIL FILTER BAG,FRYER OIL FILTER BAG,COOKING OIL FILTER BAG,FRYER OIL FILTER BAG |

| Port | Sanand |

| Delivery Time | 1-2 week |

| Packaging Details | CARTON BOX |

A fryer oil filter bag is a disposable or reusable bag designed to filter and purify cooking oil in commercial deep fryers or home fryers. These bags are typically made from heat-resistant materials and are used to remove impurities, crumbs, and debris from the cooking oil, which can accumulate during the frying process. Filtering the oil helps extend its lifespan, improve the quality of fried foods, and reduce the need for frequent oil changes.

Here's how a fryer oil filter bag is typically used:

Preparation: Allow the cooking oil to cool down to a safe temperature, usually around 150-180 degrees Fahrenheit (65-82 degrees Celsius).

Placement: Place the fryer oil filter bag inside a clean and empty container that can hold the filtered oil.

Pouring: Carefully pour the used cooking oil into the bag. The bag will capture impurities and particles as the oil passes through it.

Filtering: Lift the bag with the filtered oil, allowing the oil to flow back into the fryer or storage container. The bag will trap debris, leaving behind cleaner oil.

Disposal or Storage: Dispose of the debris-filled bag properly or store it for future use if it's a reusable filter bag.

Fryer oil filter bags come in various sizes and materials to fit different fryer models and capacities. Some are disposable and are meant to be discarded after a single use, while others are designed to be cleaned and reused multiple times, which can be more cost-effective in the long run.

Regularly filtering and maintaining cooking oil can improve the taste and quality of fried foods and save on oil costs by prolonging the oil's usability. It also reduces the environmental impact of oil disposal and minimizes the need for frequent oil changes.

| Business Type | Manufacturer, Supplier |

| Size | 22.3 |

| Filtration Capacity | Up To 66 LPM |

| Voltage | 110-120 V |

| Condition | New |

| Material | SS (Body) |

| Weight | 123 Lbs |

| Tank Volume | 137 lbs wth built in oil level sensor |

| Pumping Capacity | Up to 35 LPM |

| Particle Uptake | 10.7 Kg |

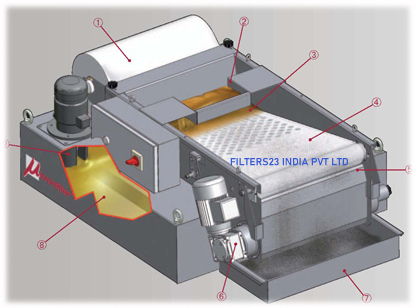

Fryer Oil Filter Machine

Filters23 India fryer oil filter machine, also known as a deep fryer oil filtration system, is a piece of equipment used in commercial kitchens, particularly in restaurants and foodservice establishments, to extend the lifespan of cooking oil used in deep fryers. These machines are designed to filter and clean frying oil, removing impurities, food particles, and contaminants to maintain the quality of the oil, reduce waste, and improve the taste and texture of fried foods. Here's how a fryer oil filter machine typically works and its key features:

How a Fryer Oil Filter Machine Works:

- Filtration System: The machine is equipped with a filtration system that can include various components like a filter pump, filter housing, filter media (usually a disposable or reusable filter paper), and sometimes a separate holding tank for the used oil.

- Hot Oil Handling: Fryer oil filter machines are designed to handle hot oil. They can be used while the oil is still hot, allowing for continuous frying operations.

- Filtering Process: The oil from the deep fryer is pumped or drained into the filtration system, where it passes through the filter media. The filter media captures impurities, food particles, and other contaminants present in the oil.

- Cleaned Oil Return: The filtered and cleaned oil is then pumped or returned to the fryer for reuse. This process improves the quality and clarity of the oil, resulting in better-tasting and more visually appealing fried foods.

- Waste Collection: Any solid debris or contaminants captured by the filter media are typically collected in a waste container for easy disposal.

- Key Features of Fryer Oil Filter Machines:

- Various Sizes: Fryer oil filter machines come in various sizes and capacities to suit the needs of different commercial kitchens, from small restaurants to large food production facilities.

- Portability: Many models are designed to be portable, allowing easy movement between fryers and making them suitable for use with multiple fryers.

- Quick Filtration: These machines are designed for quick and efficient filtration, minimizing downtime during the cooking process.

- Temperature Control: They can handle hot oil, often allowing for continuous filtering without the need to cool down the oil.

- User-Friendly Controls: Most machines have user-friendly controls for easy operation.

- Safety Features: They may include safety features to prevent spills and accidents, such as splash guards or locking mechanisms.

- Extended Oil Life: Regular use of a fryer oil filter machine can significantly extend the lifespan of frying oil, reducing the frequency of oil changes and associated costs.

- Improved Food Quality: Cleaner oil results in better-tasting and more visually appealing fried foods.

- Fryer oil filter machines are essential in commercial kitchens where deep frying is a common cooking method. They help maintain the quality of cooking oil, reduce waste, and improve the consistency and taste of fried foods. The choice of a specific machine depends on the size of the fryer, the volume of frying done, and the filtration needs of the kitchen. Properly maintained oil can lead to cost savings and higher customer satisfaction.

| Business Type | Manufacturer, Exporter |

| Usage | COOKING OIL FILTRATION |

| Features | FRYER OIL FILTER |

| Brand Name | FILTERS23,FILTERS23 |

| Material | STAINLESS STEAL |

| Driven Type | Electric |

| Color | Light Grey |

| Condition | NEW |

| Power | 7-9kw, 9-12kw |

| Automatic Grade | Semi Automatic |

| Application | COOKING OIL FILTRATION |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 110V, 220V |

| Type | FRYER OIL FILTER,FRYER OIL FILTRATION,COOKING OIL FILTRATION,FRYER OIL FILTRATION,COOKING OIL FILTRATION |

| Efficiency | 5 MICRON |

| Warranty | 1 YEAR |

| After-Sales Service Provided | 1 Year |

| Country of Origin | India,India |

| Warrenty | 1 Year |

| Filtration | COOKING OIL |

| Product Code | FTI-FC-50/30 |

| Port | Sanand |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 2-5 Weeks |

| Packaging Details | CARTON WITH PLYWOOD |

Fryer Oil Filter System

Introduction

Ensure the longevity of your frying oil and the quality of your food with our advanced fryer oil filter system. Designed specifically for restaurants and food stalls, this essential tool helps maintain the purity of your oil, leading to better-tasting food and cost savings.

Key Features

- High-Efficiency Filtration System: Our fryer oil filter system uses state-of-the-art filtration technology to remove impurities and extend the life of your frying oil.

- Easy-to-Use Interface: With a user-friendly design, the system ensures hassle-free operation, even during busy hours.

- Durable Construction: Built with high-grade stainless steel, this filter system is designed to withstand the rigors of daily use in commercial kitchens.

- Mobility and Compact Design: Equipped with sturdy wheels and a compact build, it can be easily moved and stored, fitting seamlessly into any kitchen layout.

- Advanced Filtering Material: Includes specially designed food-grade filter sheets, optimized for capturing fine particles and ensuring superior oil quality.

Technical Specifications

- Material: High-grade stainless steel

- Filtration Capacity: Capable of filtering up to 20 liters of oil per cycle

- Efficiency: Removes 99% of particles as small as 5 microns

- Filter Paper: High-efficiency, food-grade filter sheets with a fine mesh structure

Benefits

Using our fryer oil filter system, you can significantly prolong the life of your frying oil, ensuring a consistent, high-quality food output. This system not only reduces your operational costs by minimizing oil waste but also enhances safety and cleanliness in your kitchen environment.

| Business Type | Manufacturer, Exporter |

| Filtration | COOKING OIL |

| Warrenty | 1 Year |

| After-Sales Service Provided | 1 Year |

| Automatic Grade | Semi Automatic |

| Driven Type | Electric |

| Features | FRYER OIL FILTER |

| Country of Origin | India,India |

| Warranty | 1 YEAR |

| Efficiency | 5 MICRON |

| Type | FRYER OIL FILTER,FRYER OIL FILTER SYSTEM,FYER OIL FILTER SYSTEM,FRYER OIL FILTRATION,COOKING OIL FILTRATION,FRYER OIL FILTER,COOKING OIL FILTRATION |

| Voltage | 110V, 220V |

| Certification | CE Certified, ISO 9001:2008 |

| Condition | NEW |

| Color | Light Grey |

| Material | STAINLESS STEAL |

| Brand Name | FILTERS23,FILTERS23 INDIA PVT LTD,FILTERS23 |

| Application | COOKING OIL FILTRATION |

| Product Code | FTI-US-20/55 |

| Port | Sanand |

| Payment Terms | L/C, D/A, D/P, T/T |

| Delivery Time | 2-5 Weeks |

| Packaging Details | CARTON WITH PLYWOOD |

-

Fryer Oil Filter System

Introduction

Ensure the longevity of your frying oil and the quality of your food with our advanced fryer oil filter system. Designed specifically for restaurants and food stalls, this essential tool helps maintain the purity of your oil, leading to better-tasting food and cost savings.

Key Features

- High-Efficiency Filtration System: Our fryer oil filter system uses state-of-the-art filtration technology to remove impurities and extend the life of your frying oil.

- Easy-to-Use Interface: With a user-friendly design, the system ensures hassle-free operation, even during busy hours.

- Durable Construction: Built with high-grade stainless steel, this filter system is designed to withstand the rigors of daily use in commercial kitchens.

- Mobility and Compact Design: Equipped with sturdy wheels and a compact build, it can be easily moved and stored, fitting seamlessly into any kitchen layout.

- Advanced Filtering Material: Includes specially designed food-grade filter sheets, optimized for capturing fine particles and ensuring superior oil quality.

Technical Specifications

- Material: High-grade stainless steel

- Filtration Capacity: Capable of filtering up to 20 liters of oil per cycle

- Efficiency: Removes 99% of particles as small as 5 microns

- Dimensions: 24 x 18 x 36 inches (diffrent tank size also)

- Filter Paper: High-efficiency, food-grade filter sheets with a fine mesh structure

Benefits

Using our fryer oil filter system, you can significantly prolong the life of your frying oil, ensuring a consistent, high-quality food output. This system not only reduces your operational costs by minimizing oil waste but also enhances safety and cleanliness in your kitchen environment.

| Business Type | Manufacturer, Exporter |

| Application | COOKING OIL FILTER |

| Brand Name | FILTERS23,FILTERS23 |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 9-12kw |

| Certification | ISO 9001:2008,CE Certified |

| Voltage | 220V |

| Warranty | 1year |

| After-Sales Service Provided | 1 year |

| Type | FRYER OIL FILTER,COOKING OIL FILTRESTION,FRYER OIL FILTER,COOKING OIL FILTRATION |

| Product Code | FTI-EU-40 |

| Port | Sanand |

| Payment Terms | Other |

| Delivery Time | 2-5 Weeks |

| Packaging Details | CARTON WITH PLYWOOD |

Fryer Oil Filter System

Introduction

Ensure the longevity of your frying oil and the quality of your food with our advanced fryer oil filter system. Designed specifically for restaurants and food stalls, this essential tool helps maintain the purity of your oil, leading to better-tasting food and cost savings.

Key Features

- High-Efficiency Filtration System: Our fryer oil filter system uses state-of-the-art filtration technology to remove impurities and extend the life of your frying oil.

- Easy-to-Use Interface: With a user-friendly design, the system ensures hassle-free operation, even during busy hours.

- Durable Construction: Built with high-grade stainless steel, this filter system is designed to withstand the rigors of daily use in commercial kitchens.

- Mobility and Compact Design: Equipped with sturdy wheels and a compact build, it can be easily moved and stored, fitting seamlessly into any kitchen layout.

- Advanced Filtering Material: Includes specially designed food-grade filter sheets, optimized for capturing fine particles and ensuring superior oil quality.

Technical Specifications

- Material: High-grade stainless steel

- Filtration Capacity: Capable of filtering up to 20 liters of oil per cycle

- Efficiency: Removes 99% of particles as small as 5 microns

- Filter Paper: High-efficiency, food-grade filter sheets with a fine mesh structure

Benefits

Using our fryer oil filter system, you can significantly prolong the life of your frying oil, ensuring a consistent, high-quality food output. This system not only reduces your operational costs by minimizing oil waste but also enhances safety and cleanliness in your kitchen environment.

| Business Type | Manufacturer |

| Brand | Filter23 India Pvt Ltd |

| Color | White |

| Certification | ISO 9001:2008 |

| Pattern | Plain |

| Condition | New |

| Packaging Type | bundles |

| Port | SANAD |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | bundles |

Frying oil filter paper roll

Frying oil filters are devices or equipment used in commercial kitchens, especially in restaurants and foodservice establishments, to filter and maintain the quality of cooking oil used in deep frying. These filters are essential for extending the life of frying oil, ensuring the taste and quality of fried foods, and reducing waste. Here are some key features and benefits of frying oil filters:

Continuous Filtration: Frying oil filters are designed for continuous use and can filter hot cooking oil while the fryer is operational. This continuous filtration helps remove impurities, food particles, and contaminants from the oil as it circulates through the filter system.

Filter Media: These filters typically use filter paper or filter cartridges made from materials specifically designed for use with hot oil. The filter media can vary in mesh size to capture different-sized particles and impurities.

Improved Food Quality: Filtering the oil removes particles and impurities that can negatively impact the taste and appearance of fried foods, ensuring a consistent and high-quality product.

| Business Type | Manufacturer |

| Size | customize |

| Brand Name | FILTERS23 INDIA PVT LTD |

| Color | White |

| Type | FRYMASTER FRYER FILTER BAGS |

| Country of Origin | India |

| Port | SANAD |

| Packaging Details | BOX PACKING |

FRYMASTER FRYER FILTER BAGS

| Business Type | Manufacturer, Exporter |

| Size | customize |

| Brand Name | FILTERS23 INDIA PVT LTD |

| Color | Creamy, White |

| Type | HENY PENY FRYER FILTER BAGS |

| Country of Origin | India |

| Port | SANAD |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | BOX PACKING |

HENY PENY FRYER FILTER BAGS

| Business Type | Manufacturer, Supplier |

| Brand Name | FILTERS23 |

| Material | Non Woven, wood pulp |

| Color | White |

| Shape | as per requirement |

| Application | Liquid Filter,Oil Filter |

| Pattern | Plain |

| Type | Liquid Filter Bag, FRYER OIL FILTER BAG |

| Country of Origin | India |

| Diameter | 101 -152.4 Mm |

| Medium Material | Non-Woven |

| Bag Type | Mesh Filter Bag |

| Execution | Sewn |

| Micron Rating | 75-100 |

| Port | Sanand |

| Delivery Time | 1-2 week |

| Packaging Details | CARTON TYPE BOX |

A fryer oil filter bag is a disposable or reusable bag designed to filter and purify cooking oil in commercial deep fryers or home fryers. These bags are typically made from heat-resistant materials and are used to remove impurities, crumbs, and debris from the cooking oil, which can accumulate during the frying process. Filtering the oil helps extend its lifespan, improve the quality of fried foods, and reduce the need for frequent oil changes.

Here's how a fryer oil filter bag is typically used:

Preparation: Allow the cooking oil to cool down to a safe temperature, usually around 150-180 degrees Fahrenheit (65-82 degrees Celsius).

Placement: Place the fryer oil filter bag inside a clean and empty container that can hold the filtered oil.

Pouring: Carefully pour the used cooking oil into the bag. The bag will capture impurities and particles as the oil passes through it.

Filtering: Lift the bag with the filtered oil, allowing the oil to flow back into the fryer or storage container. The bag will trap debris, leaving behind cleaner oil.

Disposal or Storage: Dispose of the debris-filled bag properly or store it for future use if it's a reusable filter bag.

Fryer oil filter bags come in various sizes and materials to fit different fryer models and capacities. Some are disposable and are meant to be discarded after a single use, while others are designed to be cleaned and reused multiple times, which can be more cost-effective in the long run.

Regularly filtering and maintaining cooking oil can improve the taste and quality of fried foods and save on oil costs by prolonging the oil's usability. It also reduces the environmental impact of oil disposal and minimizes the need for frequent oil changes.

| Business Type | Manufacturer, Exporter |

| Size | customize |

| Brand Name | FILTERS23 INDIA PVT LTD |

| Color | Creamy, White |

| Application | KITCHEN |

| Feature | Eco Friendly |

| Type | FRYER OIL FILTER BAGS |

| Port | SANAD |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | BOX PACKING |

PITCO FRYER FILTER BAGS

| Business Type | Manufacturer, Exporter |

| Application | Fryer Oil Filtration |

| Brand Name | Filters23 India Pvt Ltd |

| Material | Stainless Steel |

| Finishing | Matte, Polished |

| Material Grade | S S Fryer Oil Filter System |

| Shape | Square |

| Color | Polished |

| Condition | New |

| Type | Fryer Oil Filter System |

| Warranty | 1 Year |

| Country of Origin | India |

| Port | SANAD |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | wooden box |

Filters23 India fryer oil filter machine, also known as a deep fryer oil filtration system, is a piece of equipment used in commercial kitchens, particularly in restaurants and foodservice establishments, to extend the lifespan of cooking oil used in deep fryers. These machines are designed to filter and clean frying oil, removing impurities, food particles, and contaminants to maintain the quality of the oil, reduce waste, and improve the taste and texture of fried foods. Here's how a fryer oil filter machine typically works and its key features:

How a Fryer Oil Filter Machine Works:

1. Filtration System: The machine is equipped with a filtration system that can include various components like a filter pump, filter housing, filter media (usually a disposable or reusable filter paper), and sometimes a separate holding tank for the used oil.

2. Hot Oil Handling: Fryer oil filter machines are designed to handle hot oil. They can be used while the oil is still hot, allowing for continuous frying operations.

3. Filtering Process: The oil from the deep fryer is pumped or drained into the filtration system, where it passes through the filter media. The filter media captures impurities, food particles, and other contaminants present in the oil.

4. Cleaned Oil Return: The filtered and cleaned oil is then pumped or returned to the fryer for reuse. This process improves the quality and clarity of the oil, resulting in better-tasting and more visually appealing fried foods.

5. Waste Collection: Any solid debris or contaminants captured by the filter media are typically collected in a waste container for easy disposal.

Key Features of Fryer Oil Filter Machines:

1. Various Sizes: Fryer oil filter machines come in various sizes and capacities to suit the needs of different commercial kitchens, from small restaurants to large food production facilities.

2. Portability: Many models are designed to be portable, allowing easy movement between fryers and making them suitable for use with multiple fryers.

3. Quick Filtration: These machines are designed for quick and efficient filtration, minimizing downtime during the cooking process.

4. Temperature Control: They can handle hot oil, often allowing for continuous filtering without the need to cool down the oil.

5. User-Friendly Controls: Most machines have user-friendly controls for easy operation.

6. Safety Features: They may include safety features to prevent spills and accidents, such as splash guards or locking mechanisms.

7. Extended Oil Life: Regular use of a fryer oil filter machine can significantly extend the lifespan of frying oil, reducing the frequency of oil changes and associated costs.

8. Improved Food Quality: Cleaner oil results in better-tasting and more visually appealing fried foods.

Fryer oil filter machines are essential in commercial kitchens where deep frying is a common cooking method. They help maintain the quality of cooking oil, reduce waste, and improve the consistency and taste of fried foods. The choice of a specific machine depends on the size of the fryer, the volume of frying done, and the filtration needs of the kitchen. Properly maintained oil can lead to cost savings and higher customer satisfaction.