Filtration Systems

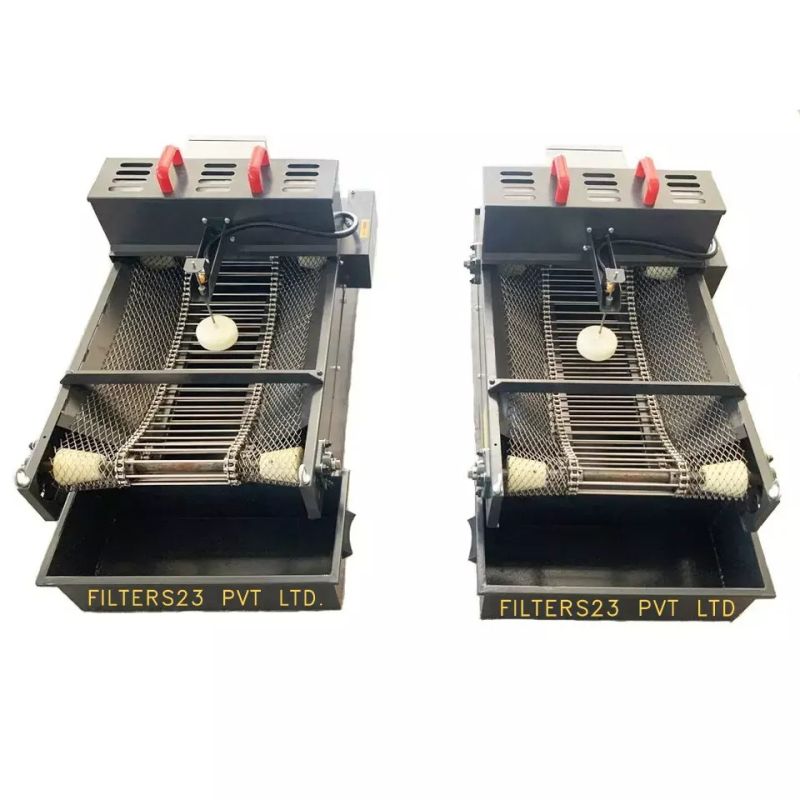

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of 50 Lpm Coolant Magnetic Separator, Automatic Compact Band Filter, Automatic Paper Band Cum Magnetic Separator, Automatic Paper Band Filtration System, Band Filter Paper Roll, Centralized Coolant System, Centralized Filtration System, Coolant Sump Cleaner, Gravity Band Filter, Gravity Paper Band Filter, Magnetic Coolant Separator, Magnetic Separator Paper Band Filtration, Paper Band Filter, Stainless Steel Automatic Paper Band Filter and Stainless Steel Bag Filter Housings from Mulchand.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Warranty | 1 Year |

| Phase | Three Phase |

| Automatic Grade | Automatic |

| Color | Grey |

| Brand Name | Filters23 |

| Finishing | Polished |

| Condition | New |

| Usage | Industrial |

| Certification | CE Certified |

| Type | Magnetic Drum Separator,megnatic Coolant Separator |

| Port | sanand |

| Payment Terms | L/C, D/A, D/P, T/T |

| Packaging Details | export type wooden box |

Performance Enhancing Features

magnetic force of the ferrite magnets and provides an effective pushing action once every revolution to help move swarf down the chute while forcing most of the coolant back into the coolant tank.

The Barnes unit is available in five standard and five rare earth models to accommodate a wide range of flow rates and machine configurations.

Additional information

|

Applications - Single & Multiple Machines |

Machining With Standard Magnets Grinding with Standard & Rare Earth Magnets |

|

Features |

Powerful Permanent Ferrite Magnets Filter to 20 Microns |

| Business Type | Manufacturer, Supplier |

| Voltage | 220V |

| Material | Mild Steel |

| Phase | Single Phase |

| Automatic Grade | Automatic |

| Surface Finish | Color Coated |

| Clarity level | 75 microns |

| Range | 30 LPM |

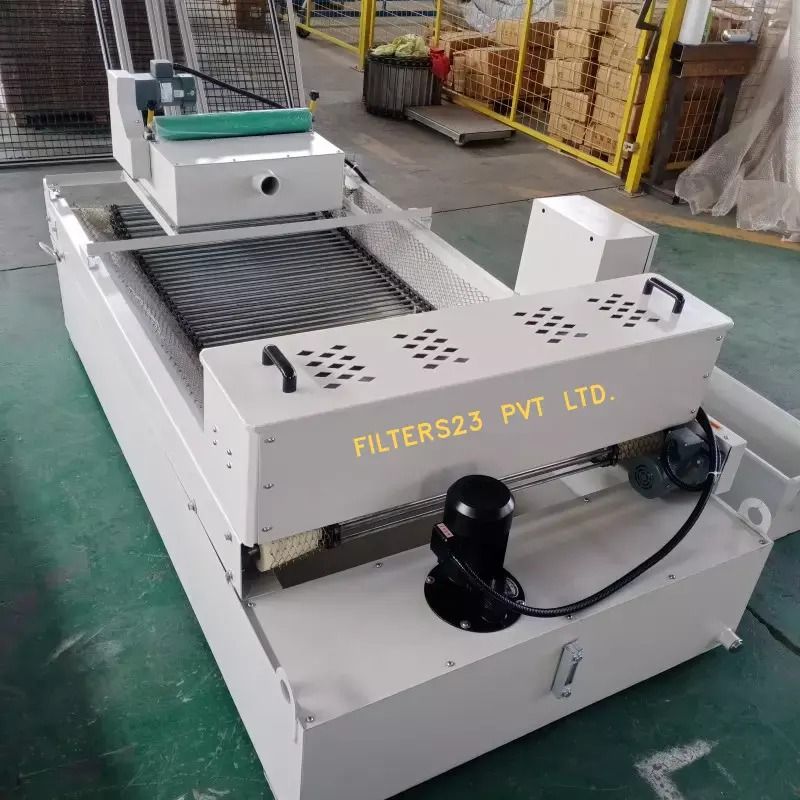

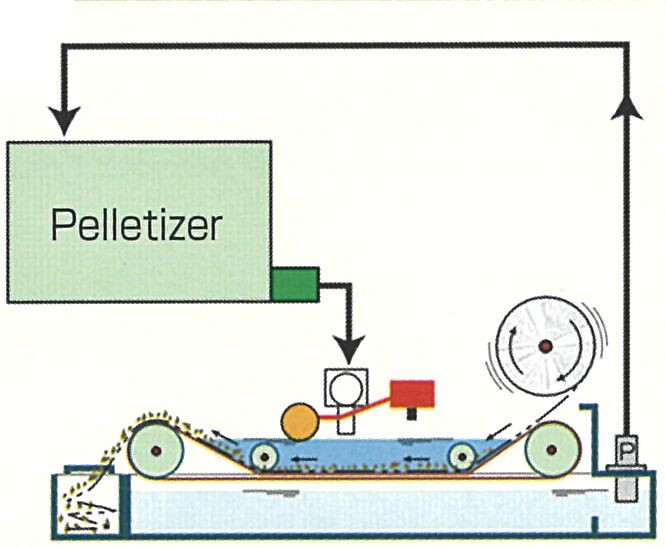

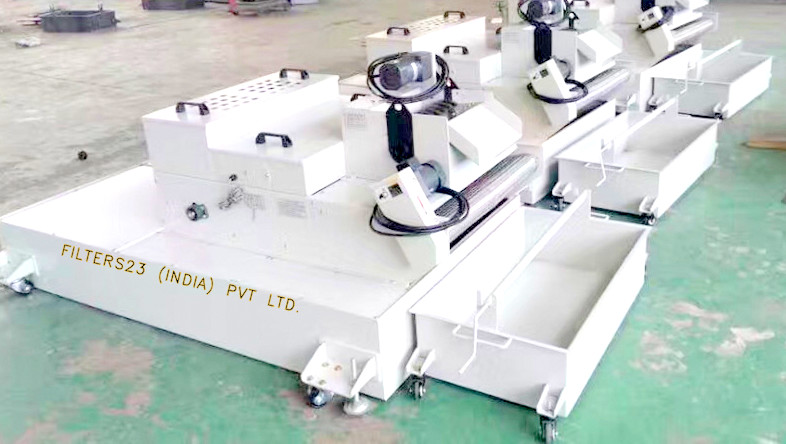

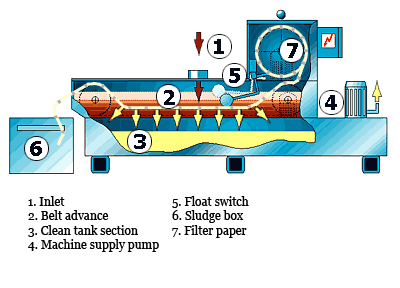

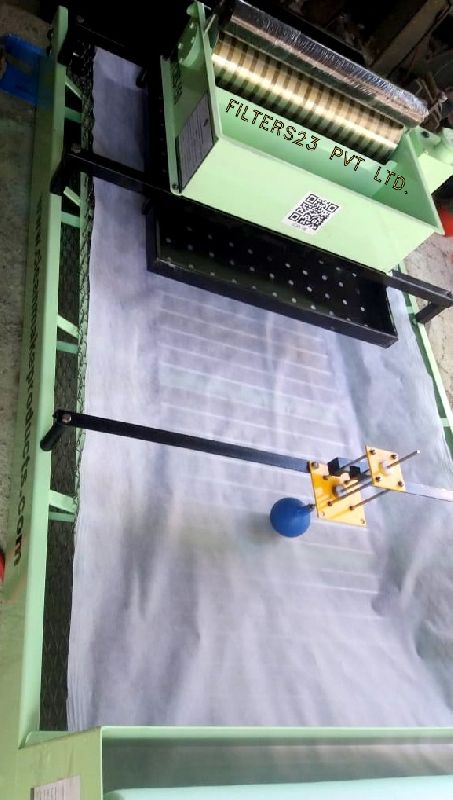

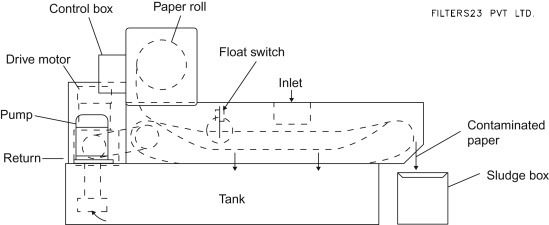

COMPACT BAND FILTERS

Compact Band Filter is designed to filter ferrous and non-ferrous solid particles from liquid with high degree of purification using paper as filter media to enhance life of liquid and protect surface finish of products. Compact Band Filter works both with water base emulsion coolant as and oil(neat oil).MOC of Compact Band Filter is mild steel, SS-304 and SS-316.

The fluid with dirt is passed to compact band filter through inlet pipe. Float actuated drives motion and indexes dirty filter paper.

A compact band filtration system is a type of filtration system designed to efficiently remove impurities, particles, or contaminants from a fluid, typically a liquid, within a specific band or range of particle sizes. These systems are commonly used in industrial and commercial applications to ensure the quality and cleanliness of fluids in a space-saving and cost-effective manner.

General Description:

Transfer pump is fitted on Dirty coolant tank to supply the coolant to the filtration system. Operation logic of Transfer Pump is based on the Level Indicators on Dirty and Clean tanks.

Once the filtration system is switched ON, Transfer pump is started based on high level in Dirty tank. Transfer Pump is cut off if coolant level goes low level in dirty tank or coolant level goes high level of clean tank.

Compact Band Filter is placed on top of Clean coolant tank. Compact band filter uses paper filter to remove impurities from the coolant and filtered coolant gets collected in Clean tank.

Supply Pump is mounted on the Clean tank of filtration system. Coolant from Clean tank is transferred to machine using this pump.

This Supply Pump is started based on the signal from the machine. Supply Pump is switched off if coolant level goes low in clean tank.

Key features and components of a compact band filtration system may include:

Filter Media: The heart of any filtration system is the filter media, which can be made from various materials such as paper, fabric, metal, or synthetic materials. The choice of filter media depends on the type and size of contaminants to be removed.

Filter Element: Compact band filtration systems typically use filter elements that are designed to trap particles within a specific size range. These filter elements can come in different shapes and configurations, including cartridges, bags, or screens.

Inlet and Outlet Connections: These systems have inlet and outlet connections to allow the fluid to enter and exit the filtration system. These connections are typically designed for easy integration into existing pipelines or fluid systems.

Control System: Advanced filtration systems may incorporate a control system to automate filtration processes, monitor filter performance, and trigger cleaning cycles as needed.

Size and Portability: Compact band filtration systems are designed to take up minimal space while still providing effective filtration. This is especially important in situations where space is limited or where mobility is required.

Application-Specific Design: These filtration systems can be customized to meet the specific requirements of different industries and applications, including oil and gas, automotive, food and beverage, pharmaceuticals, and more.

Maintenance and Serviceability: Easy access for maintenance and replacement of filter elements is a crucial consideration in the design of compact band filtration systems to minimize downtime and maintenance costs.

Features :

Suitable for fine filtration.

Filtration capacity.

Very low maintenance.

Totally automatic operation.

Very compact design for individual machine.

Can be customized to suit your requirement.

Filtration capacity: 10 lpm to 3000 lpm

Advantages :

Increase tool life

Increase surface finish of components.

Extending coolant life

Reduces hazards waste

Cleaner working environment

Reduces machine down time

Increased machine output.

Application:-

Bearing industry.

Auto component manufacturers.

Automobile manufacturers.

Cold Rolling mill.

Waste water treatment plants.

Food processing.

| Business Type | Manufacturer, Supplier |

| Phase | Three Phase |

| Power Source | Electric |

| Voltage | 220 V |

| Material | Mild Steel |

| Capacity | 1200 LPM |

| Condition | New |

| Automatic Grade | Automatic |

| Frequency | 50 Hz |

| Weight | 200 kg |

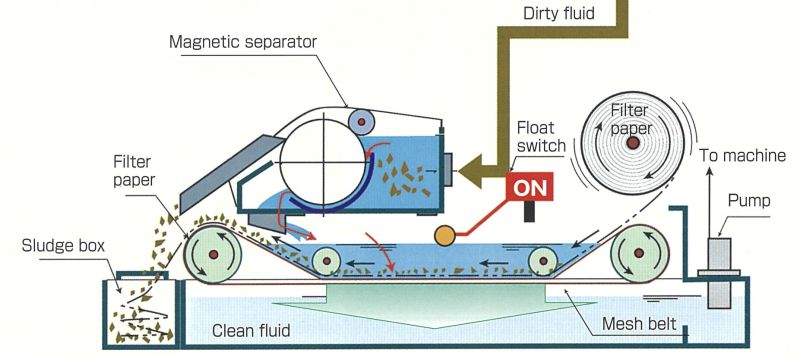

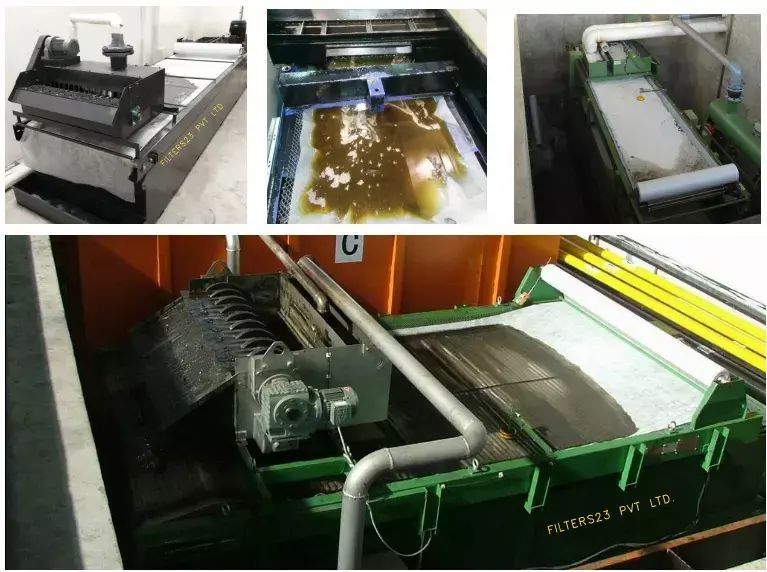

Paper Band Cum Magnetic Separator

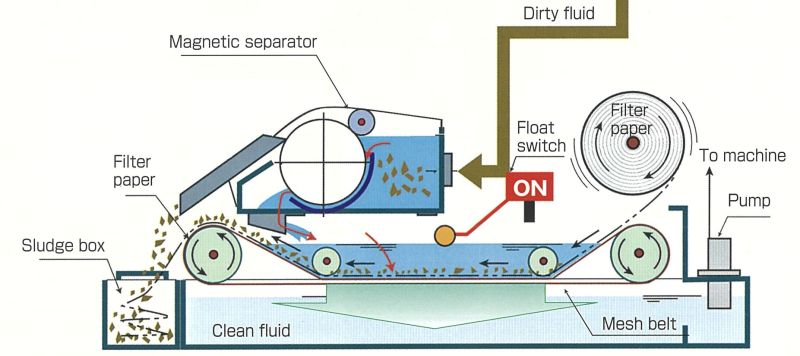

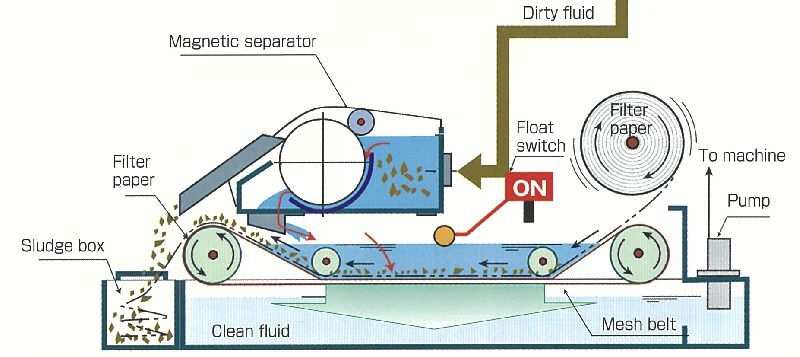

FILTERS23 INDIA`S paper band cum magnetic separator is a machine or device used in industrial settings to separate ferrous (iron-containing) particles from other materials, typically in a manufacturing or recycling process. This type of equipment combines two separate functions: paper band filtration and magnetic separation.

Paper Band Filtration: A paper band filtration system is used to filter out solid particles from a liquid or coolant. In industrial processes like metal machining or grinding, a coolant is often used to cool the cutting tools and remove debris. As the coolant circulates, it can become contaminated with metal shavings and other solid particles. The paper band filtration system uses a continuous loop of filter paper or a similar material to trap and remove these contaminants from the coolant, allowing the clean coolant to be reused.

Magnetic Separation: Magnetic separation is a method used to separate magnetic materials (such as iron and steel) from non-magnetic materials. In this process, a magnetic field is applied to a mixture of materials, causing the magnetic particles to be attracted to a magnetic surface or separator, while non-magnetic materials remain unaffected.

A paper band cum magnetic separator combines these two processes into a single machine. Here's how it typically works:

The contaminated coolant or liquid containing both solid particles and magnetic materials is fed into the system.

The paper band filtration system filters out the solid particles (including non-magnetic materials) from the liquid, as it passes through the filter paper.

Simultaneously, a magnetic separator within the machine uses a magnetic field to attract and separate the ferrous or magnetic particles from the remaining liquid.

The separated magnetic particles are collected in a separate container or bin, while the clean liquid is returned to the industrial process for reuse.

This type of equipment is commonly used in industries like metalworking, automotive manufacturing, and recycling where the separation of ferrous contaminants from liquids is essential for maintaining the quality of products and extending the life of cutting tools and equipment.

The specific design and operation of a paper band cum magnetic separator can vary depending on the manufacturer and the requirements of the industrial process it serves.

| Business Type | Manufacturer, Supplier |

| Flow Rate | 1200 LPM |

| Voltage | 240 V |

| Material | Mild Steel |

| Condition | New |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Frequency | 50 Hz |

| Filter Type | Paper Band |

| Surface Treatment | Powder Coated |

| Paper Size | 1300 mm |

| Business Type | Manufacturer, Supplier |

| Color | White |

| Condition | New |

| Country of Origin | India |

| Material Grade | 20 GSM |

| Material | Non Woven |

| Length | Upto 150 Meter |

| Width | 50 mm |

| Usage | For Filtration |

| Thickness | Upto 10 mm |

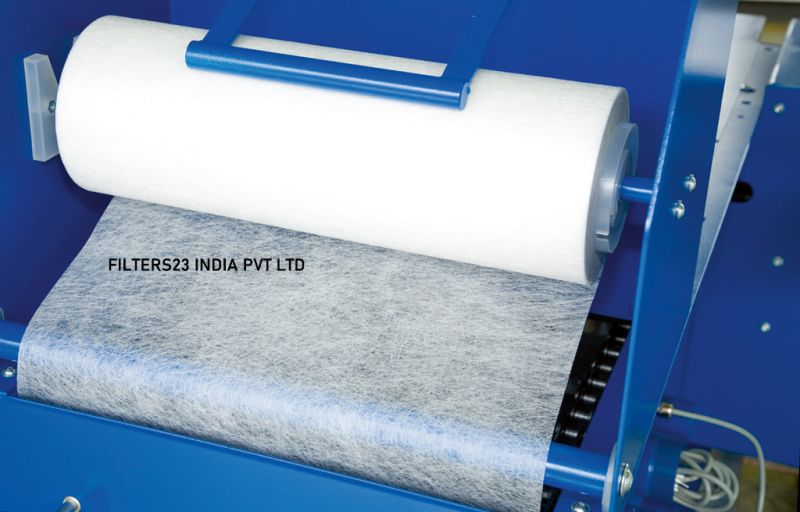

Paper band filter paper rolls

Filters23 India’s Paper band filter paper rolls, also known as filter media or filter paper rolls, are specialized filter materials used in paper band or paper belt filtration systems. These systems are commonly used in industrial applications, particularly in metalworking and machining processes, to filter out solid particles and contaminants from cutting fluids or coolants used during machining operations. Here's an overview of paper band filter paper rolls and their applications:

1. Filtration in Metalworking and Machining:

Metalworking Fluids: Paper band filtration is widely used in metalworking applications such as grinding, milling, turning, and honing, where metal chips and debris can contaminate cutting fluids or coolants.

Coolant Filtration: The primary purpose of paper band filter paper rolls is to capture and remove solid particles, metal fines, and other contaminants from the coolant, thus extending the life of the coolant and improving machining efficiency.

2. Filter Media Characteristics:

Filtration Rating: Paper band filter paper rolls are available in various filtration ratings measured in microns. The choice of filtration rating depends on the application and the desired level of filtration.

Material: These rolls are typically made from specialized filter paper or fabric materials that offer high particle retention capabilities and are compatible with the cutting fluids or coolants used in machining processes.

3. Roll Format:

Paper band filter paper rolls come in a continuous roll format, allowing users to cut the material to the required length to fit their specific filtration equipment. The rolls may have varying widths and lengths to accommodate different filter systems.

4. Operation:

In a paper band filtration system, the filter paper roll is positioned within a filtration unit, often shaped like a cylindrical drum or belt. The cutting fluid or coolant flows through the filter media as it circulates through the machining process.

As the fluid passes through the filter paper roll, solid particles and contaminants are trapped by the filter media, effectively cleaning the fluid.

Periodically, the filter paper roll may need to be advanced or replaced when it becomes saturated with contaminants. This can be done manually or automatically, depending on the system design.

5. Benefits:

Improved Machining Performance: Paper band filtration helps maintain the cleanliness of cutting fluids, which enhances tool life, surface finish, and overall machining quality.

Cost Savings: By extending the life of cutting fluids, paper band filtration reduces the need for frequent fluid replacement and disposal, resulting in cost savings.

Environmental Impact: Reducing the disposal of contaminated cutting fluids is environmentally responsible and compliant with environmental regulations.

6. Maintenance and Replacement:

Regular maintenance and replacement of the filter paper roll are necessary to maintain filtration efficiency and prevent the buildup of contaminants in the machining process.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Usage/Application | Industrial |

| Capacity | 100 LPH |

| Material | MS |

| Voltage | 220 V |

| Filter Medium Material | Paper |

| Automation Grade | Automatic |

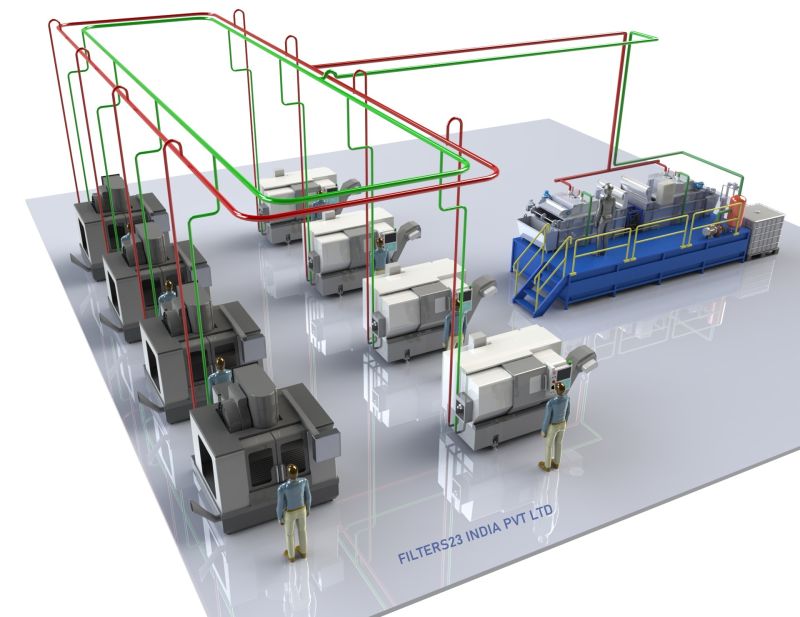

Centralized Coolant Filtration Systems

Filters 23 india centralized coolant filtration system involves several stages to maintain the quality and effectiveness of the coolant or cutting fluid used in industrial machining and metalworking processes. Below is a step-by-step overview of how these systems typically operate:

Coolant Collection: The process begins with the collection of the coolant or cutting fluid used in machining operations. This fluid is typically collected in a central reservoir or sump, which serves as the primary storage location.

Circulation: Pumps are employed to circulate the coolant from the reservoir through the filtration system and back into the machining process. This circulation ensures a continuous flow of coolant to the machining area, where it provides cooling and lubrication to cutting tools and workpieces.

Filtration: The coolant is directed through various filtration units, which are designed to remove contaminants and particulate matter. Common types of filters used in centralized coolant filtration systems include cartridge filters, bag filters, magnetic separators, and sometimes centrifuges. These filters capture solid particles, metal chips, and other impurities, preventing them from circulating in the machining process.

Cleaning and Maintenance: Over time, the filters become clogged with captured contaminants. To maintain the filtration efficiency, the system employs a cleaning mechanism. This can be done in one of two ways:

Manual Cleaning: Operators manually remove and clean the filters as needed, typically on a regular maintenance schedule.

Automatic Cleaning: Many systems are equipped with automated cleaning mechanisms that use methods like backwashing (reversing the flow through the filter), mechanical scraping, or air purging to dislodge and remove accumulated contaminants.

Monitoring and Control: Centralized coolant filtration systems often include sensors and monitoring devices to assess various parameters:

Coolant Quality: Sensors measure the quality of the coolant by detecting levels of contaminants, oil, and other factors.

Flow Rates: Flow sensors monitor the flow rate of coolant to ensure it meets the machining requirements.

Filter Condition: Sensors track the condition of filters and trigger cleaning or replacement when necessary.

Coolant Concentration: Some systems monitor the concentration of the coolant mixture and adjust it as needed by adding coolant concentrate and water.

Waste Separation: Separated contaminants, such as metal swarf and solid debris, are collected and separated from the coolant. This may involve settling tanks, centrifuges, or other separation equipment.

Coolant Reuse: After filtration and cleaning, the coolant is returned to the central reservoir. This ensures that the coolant remains in good condition for reuse in machining processes, reducing the need for frequent coolant replacements.

Disposal of Waste: Collected contaminants and waste materials are typically disposed of in an environmentally responsible manner, following local regulations.

The continuous operation of a centralized coolant filtration system helps maintain consistent coolant quality, prolongs the life of cutting tools, reduces machine downtime, and minimizes waste generation. The specific design and components of these systems may vary depending on the industry, application, and the type of contaminants present in the machining processes. Proper maintenance and monitoring of the system are essential to ensure optimal performance and extend the life of the coolant.

| Business Type | Manufacturer, Supplier |

| Material | Aluminum, Cast Iron And Forged Steel |

| Condition | New |

| Automatic Grade | Automatic |

| Voltage | 220 V |

| Country of Origin | India |

| Power Source | Electric |

| Surface Treatment | Galvanized |

| Installation Service | Yes |

Centralized Filtration Systems

Filters23 India Centralized filtration systems are used to remove impurities and contaminants from a fluid, typically water, in a centralized manner. These systems are commonly employed in various applications, including municipal water treatment plants, industrial processes, and large-scale commercial buildings. The primary purpose of centralized filtration systems is to ensure that the water or fluid meets specific quality and safety standards before distribution or use.

Here are some key components and aspects of centralized filtration systems:

Filter Media: Centralized filtration systems use various filter media to remove particles, sediment, and contaminants from the fluid. Common filter media include sand, activated carbon, diatomaceous earth, and membranes (microfiltration, ultrafiltration, and reverse osmosis membranes).

Pump System: A pump or pumping system is typically used to circulate the fluid through the filtration system. This ensures a continuous flow of water through the filters.

Filter Housing: Filter housing encases the filter media and provides a structure for the filtration process. The design of the housing can vary depending on the type of filter media and system specifications.

Pre-Treatment: In many cases, pre-treatment processes such as coagulation, flocculation, and sedimentation are employed before filtration to aid in the removal of larger particles and contaminants.

Backwashing or Cleaning Mechanism: Filters often require periodic cleaning or backwashing to remove accumulated debris and maintain their effectiveness. Automated backwashing systems are common in centralized filtration setups.

Monitoring and Control: Centralized filtration systems are equipped with monitoring and control systems that track parameters such as flow rate, pressure, and filter condition. These systems may also include alarms to alert operators of any issues.

Disinfection: In some applications, such as municipal water treatment, disinfection processes like chlorination or UV treatment may follow filtration to kill harmful microorganisms.

Distribution: After filtration and any necessary treatment, the clean water is distributed to consumers or used in industrial processes.

Centralized filtration systems offer several advantages:

Consistency: They provide a consistent level of water quality, meeting regulatory and safety standards.

Efficiency: These systems are designed for high flow rates and can handle large volumes of water or fluid.

Maintenance: Automated cleaning and monitoring reduce the need for frequent maintenance.

Cost-Effective: In many cases, centralized filtration can be more cost-effective than individual point-of-use systems.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Capacity | 500 LPH |

| Phase | Single Phase |

| Automation Grade | Automatic |

| Voltage | 240 V |

| Weight | 100 Kg |

| Material | Mild Steel |

Industrial Sump Cleaner

FILTERS23 INDIA industrial sump cleaner, also known as a sump sucker or sump cleaner system, is a specialized piece of equipment used in manufacturing and machining facilities to remove coolant, cutting fluids, or other liquids from machine tool sumps, tanks, or reservoirs. These machines are designed to streamline the process of cleaning, maintaining, and managing industrial fluids used in metalworking and machining processes. Here's how an industrial sump cleaner typically works and its key features:

How an Industrial Sump Cleaner Works:

Suction: The sump cleaner uses a powerful pump or vacuum system to create suction. A hose or suction wand is inserted into the machine tool sump or reservoir to extract the liquid.

Fluid Extraction: The suction mechanism efficiently removes the coolant, cutting fluid, or other liquids from the sump or tank, along with any accumulated swarf, chips, or contaminants.

Filtration: Many industrial sump cleaners include a filtration system to separate solids and chips from the extracted liquid. This ensures that the coolant or cutting fluid can be reused or disposed of more efficiently.

Storage: The extracted liquid is typically stored in a collection tank or drum on the sump cleaner. Some models may have multiple tanks for separating clean and dirty coolant or different fluids.

Disposal or Recycling: Depending on the condition of the extracted fluid and local regulations, the collected coolant or cutting fluid can be recycled and reused, treated for disposal, or simply disposed of properly.

Key Features of Industrial Sump Cleaners:

Versatility: Industrial sump cleaners can handle various fluids, including coolants, cutting fluids, hydraulic fluids, and more.

Efficiency: They can quickly remove liquids and solids from sumps, reducing downtime associated with manual cleaning and fluid replacement.

Filtration Options: Some sump cleaners include fine filtration systems to separate contaminants and extend the life of coolants or cutting fluids.

Portability: Many models are designed to be portable, with wheels or handles for easy maneuverability around the shop floor.

Multiple Sump Cleaning: Some industrial sump cleaners can clean multiple machine sumps before requiring discharge or disposal.

Easy Maintenance: These machines are typically designed for easy cleaning and maintenance to ensure they remain effective over time.

Reduced Environmental Impact: Efficient use of coolants and cutting fluids through recycling and reduced waste generation can lead to environmental benefits.

Safety: Proper fluid management with sump cleaners can enhance workplace safety by reducing slip hazards and the risk of exposure to harmful fluids.

Industrial sump cleaners are valuable tools in metalworking and machining operations, helping to extend the life of coolants, reduce waste, and improve the overall efficiency and cleanliness of manufacturing facilities. The choice of a specific sump cleaner model will depend on the size of the sumps, the type of fluids used, and the volume of liquid that needs to be manage.

| Business Type | Manufacturer, Supplier |

| Material | Stainless Steel |

| Country of Origin | India |

| Condition | New |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Range | 150 LPM to 2500 LPM |

| Clarity level | Up to 10 mg/lit |

| Filter Type | Coolant Filter |

Gravity Band Filter

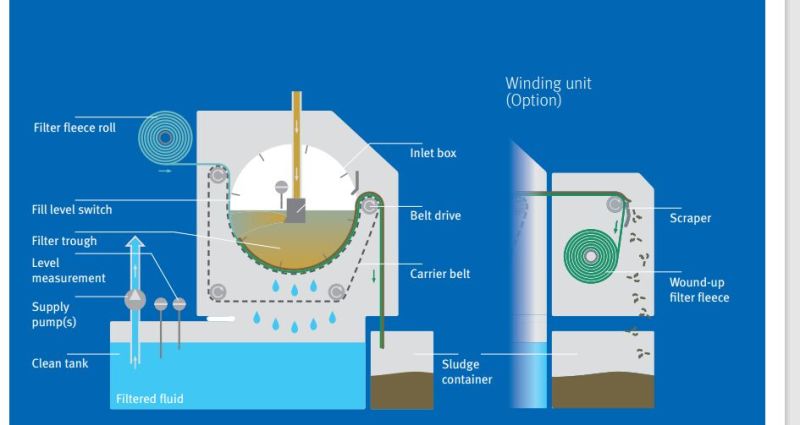

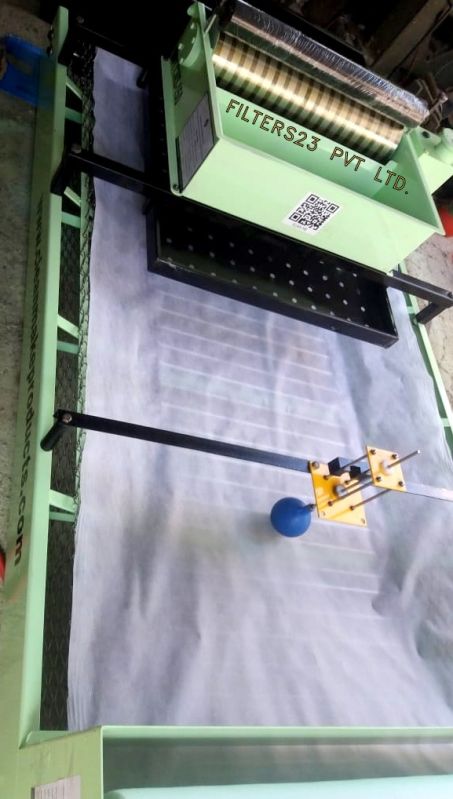

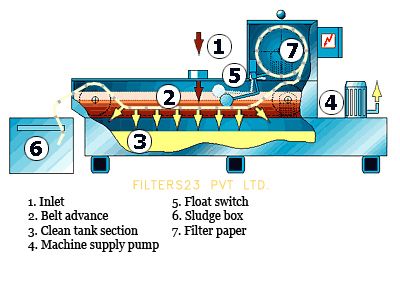

Gravity band filter is an industrial filtration system designed to remove solid particles and contaminants from a liquid using the force of gravity. It is a passive filtration method that relies on the principle of gravity to separate solids from liquids. Gravity band filters are commonly used in various manufacturing processes, especially in applications where a continuous and automatic filtration system is required. Here's how a typical gravity band filter works:

Inlet: Contaminated liquid, such as coolant or wastewater, is fed into the gravity band filter system through an inlet.

Distribution Mechanism: The incoming liquid is evenly distributed over a wide, flat surface, typically made of a porous material like a filter cloth or filter media. This distribution mechanism ensures that the liquid spreads uniformly across the filter surface.

Gravity Filtration: Gravity plays a crucial role in the filtration process. As the liquid flows over the filter surface under the influence of gravity, solid particles and contaminants are separated from the liquid and are trapped on the surface of the filter media.

Solid Accumulation: Over time, as more and more solid particles are captured, they form a layer or cake on the surface of the filter media. This layer acts as an additional filtration barrier, helping to improve the efficiency of the filter.

Clean Liquid Collection: The filtered liquid, now free of solid contaminants, flows through the filter media and is collected in a reservoir or trough beneath the filter surface.

Continuous Operation: Gravity band filters are designed to operate continuously. As long as the incoming liquid contains contaminants, the filtration process continues, and the solid particles continue to accumulate on the filter media.

Periodic Maintenance: Eventually, the filter media becomes clogged with a significant amount of solid material. At this point, the filter may need to be stopped for maintenance. The solid cake is removed from the filter media, often using a scraper or other mechanical means. After cleaning, the filter can resume operation.

Gravity band filters offer several advantages:

Continuous Operation: They can operate continuously without the need for frequent replacement of filter media.

Low Energy Consumption: These filters typically require minimal energy to operate since they rely on gravity.

Effective Filtration: They are effective at removing solid particles from liquids and are suitable for various industrial applications.

Low Maintenance: While they do require periodic maintenance to remove the accumulated solids, this is usually less frequent compared to other filtration methods.

Gravity band filters are commonly used in industries such as wastewater treatment, food processing, chemical manufacturing, and mining. The choice of filter media and the design of the system can be tailored to specific application requirements, including particle size, flow rates, and filtration efficiency.

| Business Type | Manufacturer, Supplier |

| Color | Black |

| Condition | New |

| Filter Type | Gravity |

| TBMS Capacity | 30 lpm to 2000 lpm |

| Application | Industrial |

| Automatic Grade | Automatic |

| Frequency (Hz) | 50 Hz |

Gravity Paper Band Filter

Our organization has successfully expanded its business in market owing to the offered elevated quality array of Paper Band Filter. These filters are widely used for filtering contaminated coolant and cutting oil. Our offered filters are manufactured using premium grade material and sophisticated techniques under the visionary guidance of trained professionals as per the set industry

Recommended Industry and Workpiece

Coolant processing equipment Liquid crystal and semiconductor parts Non-ferrous metal and resin

Coolant processing equipment Construction machines and construction machine parts Engine parts/Non-ferrous metal/SUS/Aluminum/Abrasive grain recovery

Coolant processing equipment Automotives/Automotive parts/Motorcycle parts Engine parts/Non-ferrous metal/SUS/Aluminum/Abrasive grain recovery

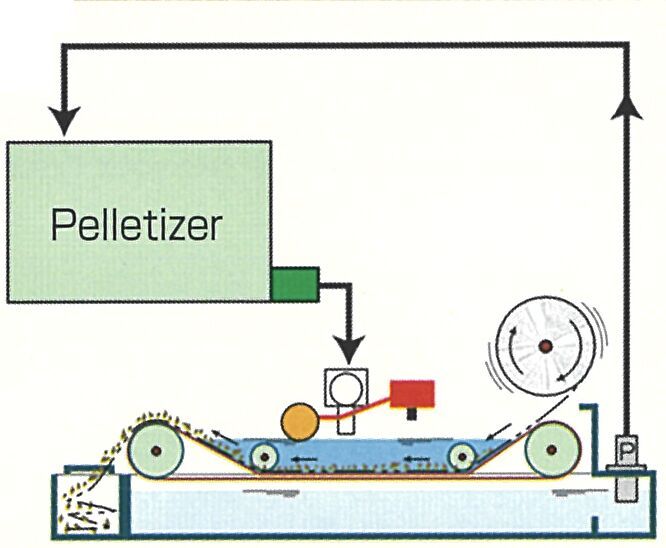

SP series Paper Filter

Separator to clean coolant using a filter paper

Filter paper can be varied to allow passage of mean particle sizes ranging from 10μ to 95 μ

Applications

Various grinding machines

Honing machines

Superfinishing machines

Cold rolling machines

Wire drawing machines

Washing machines

Pelletizers

Roll forming machines

Secondary filtration for various cutting processes

Details

Steel grinding

Cast iron

Advantages

Ideal for oil-based coolants

Unique high wall design in filter area prevents messy overflow while also allowing for improved filtration quality

Fully automatic operation

Options

Cooler

Magnetic separators

Fine filter vessels

Oil skimmers

| Business Type | Manufacturer, Supplier |

| Voltage | 220V |

| Phase | Single |

| Packaging Type | Cardboard |

| Capacity | 30 LPM |

| Material | Mild Steel |

| Coated | Powder coated |

| Finish Type | Fine Finish |

| Motor Power | 90 W |

| Automatic Grade | Fully Automatic |

| Power | 1 HP |

Coolant Magnetic Separator

Filters23 India coolant magnetic separator is a device used in industrial settings to remove ferrous (iron-based) particles from liquid coolant or cutting fluid used in machining processes. These particles can be detrimental to machinery and tools, causing wear and tear and affecting the quality of the finished products. Coolant magnetic separators help maintain the cleanliness and effectiveness of the coolant by capturing and removing these ferrous contaminants.

Here's how a coolant magnetic separator typically works:

Installation: The separator is usually installed in the coolant circulation system of a machine tool, such as a grinding machine or a machining center. It can also be installed in standalone coolant tanks.

Magnetic Field: The separator contains one or more powerful magnets. As the coolant flows through the separator, the magnetic field attracts and captures ferrous particles from the coolant.

Particle Separation: The ferrous particles, such as iron shavings, metal chips, or other magnetic contaminants, are pulled out of the flowing coolant and held onto the magnetic surface or collection area within the separator.

Cleaned Coolant: The now-cleaned coolant exits the separator and can be recirculated back into the machining process.

Maintenance: Periodically, the magnetic separator needs to be cleaned and the collected ferrous particles removed. This maintenance ensures the continued efficiency of the separator.

Coolant magnetic separators are essential in industries like metalworking, automotive manufacturing, aerospace, and more, where precision machining and the quality of finished products are critical. By removing ferrous contaminants from the coolant, these separators help extend tool life, improve machining accuracy, and reduce machine maintenance and downtime.

There are various types and designs of coolant magnetic separators available, including permanent magnetic separators and electromagnetic separators. The choice of separator depends on factors like the size and type of contaminants in the coolant, the flow rate of the coolant, and the specific requirements of the machining process.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Filtering Coolant |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 220V |

| Type | Paper Band Filtration System, Magnetic Separator Paper Band Filter,PAPER BAND FILTER,MEGNATIC SEPRATOR |

| Weight | 200-300kg, 300-400kg |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | FILTERS23 |

| Frequency | 50 |

| Port | SANAND |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 1 weeks |

| Packaging Details | EXPOR/WOODEN PACKING |

- Introducing our Paper Band cum Magnetic Separator, an innovative solution designed to optimize your filtration process by combining the benefits of paper band filtration with magnetic separation. This advanced system is engineered to efficiently remove both solid contaminants and ferrous particles from various fluids, ensuring superior filtration performance and improved product quality.

- Our Paper Band cum Magnetic Separator features a specially designed paper band filter media that effectively captures and retains solid particles, including debris, chips, and fines, from the fluid being filtered. The filter media offers a large surface area and precise filtration capabilities, allowing for efficient removal of contaminants and extending the lifespan of your fluids.

- In addition to the paper band filter, our system incorporates a powerful magnetic separator. The magnetic separator utilizes strong magnetic fields to attract and capture ferrous particles, such as iron and steel debris, from the fluid stream. This magnetic separation process enhances the purity of the fluid, preventing the particles from re-entering the filtration process and improving the overall quality of the end product.

- The system's compact design ensures easy integration into your existing filtration setup, minimizing space requirements and allowing for efficient operation. The modular construction facilitates quick and simple maintenance, including filter media replacement and cleaning of the magnetic separator, ensuring minimal downtime and optimal filtration performance.

- Our Paper Band cum Magnetic Separator also features advanced monitoring and control options. The system includes sensors and indicators that provide real-time data on filtration efficiency, magnetic separation performance, and fluid quality. This enables proactive maintenance and adjustment of filtration parameters to ensure consistent and reliable operation.

- By investing in our Paper Band cum Magnetic Separator, you can expect improved filtration efficiency, extended fluid life, reduced equipment downtime, and enhanced product quality. Experience the power of combined paper band filtration and magnetic separation technology for a more effective and efficient filtration process.

| Business Type | Supplier |

| Driven Type | Electric |

| Application | Filtering Coolant |

| Voltage | 220V |

| Type | Paper Band Filters, PAPER BAND FILTRATION |

| Warranty | 1year |

| Country of Origin | India |

| Brand | FILTERS23 |

| Phase | 2 |

| Product Code | PBFF23 |

| Port | SANAND |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 1 weeks |

| Packaging Details | EXPORT / WOODEN PACKING |

Introducing our Paper Band Filtration System, a state-of-the-art solution designed to revolutionize your industrial filtration processes. With advanced technology and superior performance, this system is specifically engineered to deliver exceptional results in various applications, including metalworking, machining, and coolant filtration.

Our Paper Band Filtration System utilizes a unique paper band filter media that effectively removes contaminants and particulates from your process fluids. The filter media consists of high-quality, specially-treated paper that offers a large surface area for efficient filtration. This ensures the removal of even the finest particles, extending the life of your fluids and enhancing the overall quality of your end products.

The system features a robust and reliable filtration unit that incorporates a precision-designed band filter mechanism. As the contaminated fluid flows through the system, the paper band filter captures and retains the impurities, preventing them from circulating back into the process. This leads to cleaner and more consistent fluid quality, minimizing equipment downtime and maintenance costs.

One of the key advantages of our Paper Band Filtration System is its exceptional longevity. The filter media can be easily replaced, allowing for continuous filtration without interruptions. The modular design of the system ensures easy maintenance and quick filter changes, optimizing productivity and reducing operational costs.

Additionally, our Paper Band Filtration System is equipped with advanced monitoring and control features. The system includes sensors and indicators that provide real-time data on filtration performance, allowing for precise control and adjustment of filtration parameters. This ensures optimal filtration efficiency and enables proactive maintenance, maximizing the lifespan of the filter media and minimizing operational risks.

In summary, our Paper Band Filtration System offers a cutting-edge solution for efficient and reliable filtration in industrial processes. With its superior performance, longevity, and advanced control capabilities, this system will significantly improve the quality of your products, increase productivity, and reduce overall operating costs. Experience the power of advanced filtration technology with our Paper Band Filtration System.

| Business Type | Manufacturer, Supplier |

| Power | 1 HP |

| Power Source | Electric |

| Material | Stainless Steel |

| Automatic Grade | Automatic |

| Voltage (V) | 230-315 V |

| Frequency | 50 Hz |

| Phase | Single Phase |

SS Paper Band Filter

A stainless steel body paper band filter is a type of industrial filtration system used to remove impurities and contaminants from liquids, often in manufacturing or processing applications. This filter consists of a stainless steel housing or body that encases a paper band or filter media.

Here's how it typically works:

Stainless Steel Housing: The filter housing is usually made of stainless steel, a durable and corrosion-resistant material. This housing contains all the components necessary for the filtration process.

Paper Band Filter Media: Inside the housing, there is a continuous paper band or filter media. This paper band is typically porous and designed to trap particles and impurities from the liquid passing through it. The choice of paper band material and its porosity can vary depending on the specific filtration requirements.

Liquid Inlet: The contaminated liquid enters the filter through an inlet. This liquid can be a coolant, lubricant, or any other industrial fluid that needs to be purified.

Filtration Process: As the liquid flows through the paper band, the filter media traps and retains particles, debris, and contaminants, allowing only clean liquid to pass through.

Clean Liquid Outlet: The purified liquid exits the filter through an outlet and is then directed to the desired process or application.

Continuous Operation: Paper band filters are often designed for continuous operation. As the paper band accumulates contaminants, it may need to be periodically replaced or cleaned. This can be done by advancing the paper band through the filter, exposing a fresh section of the media.

Maintenance: Regular maintenance, such as changing the paper band and cleaning the filter housing, is essential to ensure the filter continues to operate effectively.

Stainless steel body paper band filters are commonly used in various industries, including metalworking, automotive manufacturing, machining, and other applications where maintaining the purity of industrial fluids is critical for quality and equipment longevity. They are valued for their durability, resistance to corrosion, and ability to handle high-flow rates while effectively removing contaminants from liquids.

| Business Type | Manufacturer, Supplier |

| Material | SS 304/316 |

| Finishing | Polished |

| Color | Silver |

| Condition | New |

| Country of Origin | India |

| Product Type | Polypropylene Bag Filters |

| Usage/Application | Industrial |

| Type Of Housing | Bag Housing |

| Design | 7X32 |

| Diameter | 7 Inch |

Bag Filter Housing

filter housing, often referred to as a filter vessel or filter canister, is a container or enclosure used to hold and protect a filter element or cartridge. These filter housings are used in various industries and applications to remove contaminants or impurities from fluids such as water, air, oil, or chemicals.

"SS" in "SS filter housing" typically stands for "Stainless Steel," indicating that the filter housing is made of stainless steel material. Stainless steel is commonly used in filter housing construction because it is durable, corrosion-resistant, and suitable for use in a wide range of environments.

SS filter housings are often used in applications where cleanliness, hygiene, and resistance to corrosion are essential. Some common applications for stainless steel filter housings include:

Water Filtration: Used in residential, commercial, and industrial water treatment systems to remove sediment, particulates, and contaminants from water.

Food and Beverage Processing: Stainless steel filter housings are used in the food and beverage industry to ensure the purity of products by removing impurities and ensuring sanitary processing.

Pharmaceuticals: Stainless steel filter housings play a crucial role in pharmaceutical manufacturing, where maintaining a sterile environment is essential.

Chemical Processing: In the chemical industry, stainless steel filter housings are used to filter and purify various chemicals and solvents.

Oil and Gas: Stainless steel filter housings are employed to filter hydrocarbons and other fluids in the oil and gas industry.

Industrial Air Filtration: They are used in air filtration systems to remove particulates and contaminants from industrial air.

SS filter housings come in various sizes and configurations, and the choice of housing depends on the specific requirements of the filtration application. They can range from small, single-cartridge housings for laboratory use to large multi-cartridge housings for industrial processes.

When selecting an SS filter housing, it's important to consider factors such as flow rate, operating pressure, temperature, and the type of filter element or cartridge that will be used. Proper maintenance and regular replacement of filter elements are also crucial to ensure the effectiveness of the filtration system.