Filter Elements

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Air Filter Frame, Air Filter Media Rolls, Dust Collector Filter Bag, EDM Filters, HEPA Air Filter, Liquid Filter Bag (Industrial Filter ), Polyster Filter Sheets, PP Liquid Filter Bag, Pre Air Filter and White Polyester Air Filter Roll from Mulchand.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Shape | Square |

| Gauge | 20 Gauge |

| Features | Sturdiness,Durability,High strength |

| Material | GI |

| Size | 1240 / 1240 mm |

| Efficiency | 97-98% |

Frame air filter

Filters23`s frame air filter, also known as a furnace or HVAC (Heating, Ventilation, and Air Conditioning) filter, is an essential component of an HVAC system that helps maintain indoor air quality by trapping dust, debris, allergens, and other particles from the air. These filters are typically made of a sturdy frame, which can be made of cardboard, plastic, or metal, and a filter media that captures airborne particles. Here are some key points about frame air filters:

Types of Frame Air Filters:

Disposable Filters: These are the most common type of frame air filters and are designed to be replaced regularly, usually every 1 to 3 months, depending on usage and the filter's MERV (Minimum Efficiency Reporting Value) rating.

Washable or Permanent Filters: These filters are made of a more durable material and can be cleaned and reused multiple times. They are a more eco-friendly option but may have a higher upfront cost.

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are extremely effective at trapping tiny particles, including allergens and microorganisms. They are often used in medical settings and in homes where air quality is a top priority.

Filter Efficiency (MERV Rating): The MERV rating is a measure of a filter's efficiency in capturing particles of different sizes. The higher the MERV rating, the more efficient the filter is at removing particles from the air. However, higher MERV-rated filters may also reduce airflow in your HVAC system, so it's essential to use a filter with an appropriate rating for your system's capacity.

Regular Maintenance: Regardless of the type of filter you use, it's crucial to maintain it regularly. Disposable filters should be replaced as recommended, and washable filters should be cleaned according to the manufacturer's instructions.

Benefits: Frame air filters help improve indoor air quality by trapping particles that can cause allergies and respiratory issues. They also protect your HVAC system from dust and debris, which can extend its lifespan and improve its efficiency.

Installation: Installing a frame air filter is usually a straightforward process. You need to locate the filter slot in your HVAC system (usually near the air handler or furnace) and slide the filter into place, ensuring that it's properly oriented with the airflow direction marked on the filter frame.

Sizing: It's crucial to use the correct filter size for your HVAC system. The filter size is typically printed on the existing filter or can be found in your HVAC system's user manual.

In summary, frame air filters are essential for maintaining good indoor air quality and protecting your HVAC system. Regular maintenance and choosing the right filter with an appropriate MERV rating are key to ensuring your system works efficiently and effectively.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Weight (Gram) | 100-900 |

| Color | White |

| Width | 40 - 80 Inch |

| Material | Non Woven |

| Usage/Application | Industrial |

Air Filter media Roll

Filters23 India Synthetic air filter media refers to a type of filter material made from synthetic fibres, typically polyester or a blend of synthetic materials. This type of filter media is commonly used in various air filtration applications due to its specific properties and advantages. Here are some key characteristics and benefits of synthetic air filter media:

High Filtration Efficiency: Synthetic filter media can be engineered to provide high filtration efficiency, effectively capturing a wide range of airborne particles, including dust, pollen, pet dander, mold spores, and fine particulate matter. It is often used in filters designed to improve indoor air quality.

Low Resistance to Airflow: Synthetic media typically offers lower airflow resistance compared to some other filter materials, which can help maintain good airflow in HVAC systems. This contributes to energy efficiency and reduces the load on HVAC equipment.

Moisture Resistance: Synthetic filter media is often designed to be moisture-resistant, making it suitable for applications where filters may be exposed to humidity or moisture. It is less prone to sagging or degrading when wet compared to some other filter materials.

Durability: Synthetic media is durable and can withstand mechanical stress and handling during installation and replacement. It is less likely to tear or break compared to some paper-based filter media.

Customization: Manufacturers can customize synthetic filter media to meet specific filtration requirements. This includes adjusting the density, fiber diameter, and other parameters to optimize filtration performance for particular applications.

Washable and Reusable: Some synthetic filter media can be designed for washable and reusable filters, which can reduce long-term operating costs and waste generation.

Wide Range of Applications: Synthetic air filter media is versatile and finds applications in HVAC systems, automotive cabin air filters, industrial air filtration, air purifiers, and more.

Electrostatic Properties: Some synthetic filter media may be designed with electrostatic properties to enhance particle capture efficiency. Electrostatically charged fibers can attract and capture particles even more effectively.

Resistance to Microbial Growth: Depending on the formulation and treatment, synthetic filter media can be engineered to resist microbial growth, making it suitable for use in environments where microbiological contamination is a concern.

It's important to note that the specific properties of synthetic air filter media can vary depending on the manufacturer and the intended application. When selecting synthetic air filter media, consider factors such as filtration efficiency, pressure drop, resistance to moisture, and the type of contaminants you need to capture to ensure that it meets your filtration needs. Additionally, follow the manufacturer's recommendations for maintenance and replacement intervals to maintain optimal filtration performance.

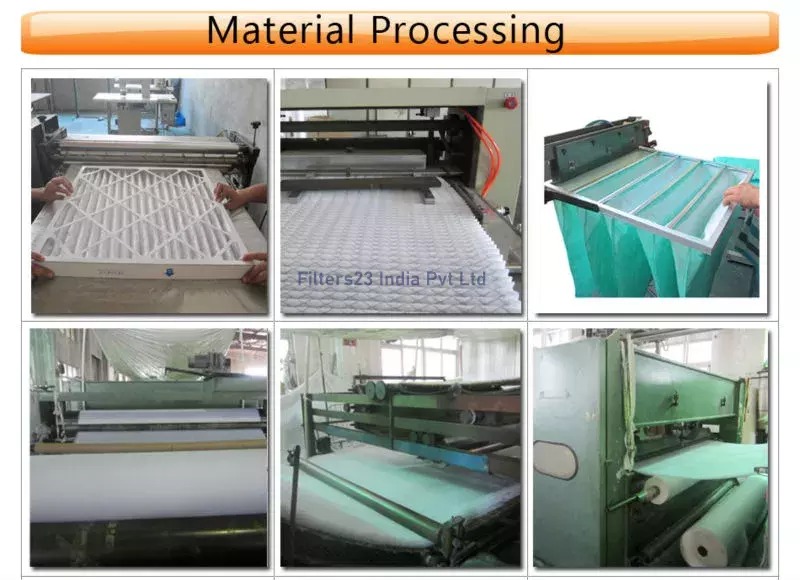

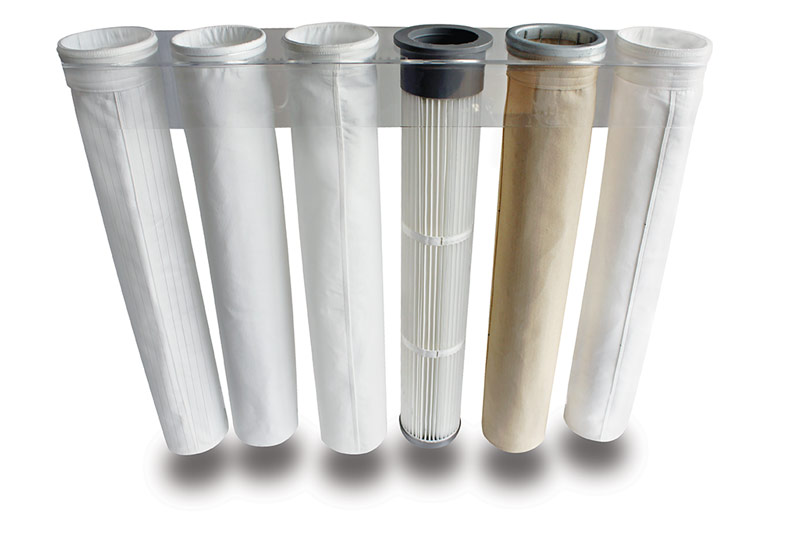

| Business Type | Manufacturer, Supplier |

| Color | White, Yellow |

| Condition | New |

| Pattern | Plain |

| Country of Origin | India |

| Bag Type | Non Woven |

| Medium Material | Fiber Glass |

| Automation Grade | Manual |

| Execution | Sewn |

Industries and applications to improve air quality and reduce airborne dust and particulate matter. These bags are designed to capture and filter out fine dust and particles from the air, preventing them from being released into the environment or workplace.

Here are some key features and information about dust collector filter bags:

Material: Dust A dust collector filter bag is an essential component of a dust collection system used in various collector filter bags are typically made from various materials, including polyester, polypropylene, fiberglass, and other synthetic or natural fibers. The choice of material depends on the specific application and the type of dust or particles being captured.

Filtration Efficiency: Filter bags are designed to have a high filtration efficiency, meaning they can capture a significant percentage of particles of a certain size or smaller. The filtration efficiency is often measured using standards such as the MERV (Minimum Efficiency Reporting Value) rating or the HEPA (High-Efficiency Particulate Air) classification for very fine particles.

Bag Design: Dust collector filter bags come in various designs, including tubular bags, envelope bags, and pleated bags. The design affects the surface area available for filtration and can impact the overall efficiency and longevity of the filter.

Size and Dimensions: The size and dimensions of filter bags can vary widely to fit different types and sizes of dust collectors and dust collection systems. It's essential to choose the right size and style of filter bag for your specific dust collection equipment.

Dust Collector Type: Filter bags are used in various types of dust collectors, including baghouses, cartridge collectors, and pulse jet collectors. The type of collector will dictate the appropriate filter bag design and material.

Maintenance and Replacement: Dust collector filter bags require regular maintenance and periodic replacement to maintain optimal performance. Over time, dust accumulation can reduce airflow and filtration efficiency, so it's crucial to follow a maintenance schedule and replace filter bags as needed.

Application: Dust collector filter bags are used in a wide range of industries and applications, including woodworking, metalworking, pharmaceuticals, food processing, cement manufacturing, and many others where dust and particulate matter are generated.

Proper selection, installation, and maintenance of dust collector filter bags are essential to ensure that they effectively capture and contain dust and particulate matter, protecting the environment and worker health. Additionally, it helps maintain the efficiency of the dust collection system and extends the life of the equipment.

dust collector filter cage

A dust collector filter cage is an essential component within a dust collector system, specifically designed to support and maintain the shape and structure of filter bags or filter cartridges. These cages play a critical role in ensuring the efficient operation of dust collectors by preventing filter bags or cartridges from collapsing or sagging under the influence of airflow and the weight of accumulated dust.

Here are some key features and information about dust collector filter cages:

Material: Filter cages are typically constructed from various materials, including carbon steel, stainless steel, or galvanized steel. The choice of material depends on factors such as the environment in which the dust collector operates and the type of dust or particulates being filtered.

Design: Filter cages come in various designs, such as round, oval, or star-shaped configurations. The design is often selected based on the shape and size of the filter bags or cartridges they support.

Size and Dimensions: Filter cages are available in a range of sizes and dimensions to accommodate different filter bag or cartridge sizes and styles. They are custom-fitted to match the specific requirements of the dust collector system.

Installation: Filter cages are installed inside the filter bags or cartridges before they are placed within the dust collector housing. Proper installation ensures that the filter bags or cartridges maintain their shape and do not collapse during operation.

Function: The primary function of a filter cage is to provide structural support to the filter media (bag or cartridge) while allowing air to pass through and be filtered. It prevents filter media from collapsing under the pressure of airflow and the weight of accumulated dust, which could lead to reduced filtration efficiency and increased maintenance needs.

Maintenance: Filter cages typically require minimal maintenance. However, they should be periodically inspected for damage or wear, and any damaged cages should be replaced promptly to ensure the continued efficiency of the dust collector.

Compatibility: It's essential to choose filter cages that are compatible with the specific type and design of filter bags or cartridges used in your dust collector system. Compatibility ensures proper fit and function.

Dust collector filter cages are crucial components of dust collection systems, helping to maintain consistent filtration performance and extending the lifespan of filter media. They are commonly used in various industries where dust and particulate matter need to be captured and removed from the air to improve air quality and protect worker health.

| Business Type | Manufacturer, Exporter |

| Brand Name | Filters23,FILTERS23,FILTERS23 |

| Material | Metal |

| Finishing | Polished |

| Shape | Round |

| Color | Black |

| Condition | New |

| Operating Type | Semi Automatic |

| Usage | EDM |

| Certification | ISO 9001:2008 |

| Packaging Type | Carton Box |

| Particle Size | MINIMUM 5 MICRON |

| Filtration Capacity | 5 MICRON |

| Specialities | Ease Of Install |

| Type | Oil Filter,EDM (electrical Discharge Machining) Filter Elements,EDM Filters,EDM (electrical Discharge Machining) Filter Elements,EDM Filter,EDM (electrical Discharge Machining) Filter Elements,EDM Filters,EDM (electrical Discharge Machining) Filter Elemen |

| Efficiency | 5 MICRON |

| Warranty | 1 Year |

| Country of Origin | India,India |

| Product Code | FTIED340 |

| Port | Sanand |

| Payment Terms | L/C, D/A, D/P |

| Delivery Time | 1-2 week |

| Packaging Details | cartoon box |

EDM filter elements are crucial components in electrical discharge machining (EDM) systems. In EDM, a controlled electrical discharge is used to erode material from a workpiece, creating the desired shape or feature. During this process, dielectric fluid is often used to facilitate the sparking and to flush away debris.

The filter elements in an EDM system serve to purify this dielectric fluid, ensuring that it remains clean and free of contaminants. This is vital for maintaining the efficiency and accuracy of the EDM process, as contaminants can interfere with the sparking and eroding action, leading to poor surface finish, dimensional inaccuracies, and increased tool wear.

Filter elements in an EDM system typically consist of materials such as porous ceramics, metal meshes, or synthetic fibers. These materials are chosen for their ability to effectively trap contaminants while allowing the dielectric fluid to pass through. Over time, as the filter elements become saturated with contaminants, they need to be replaced or cleaned to maintain optimal filtration performance.

Regular maintenance of EDM filter elements is essential for ensuring the longevity and reliability of the EDM system, as well as the quality of the machined parts.

| Business Type | Manufacturer, Supplier |

| Flow Capacity Range | Variable Based On Size |

| Country of Origin | India |

| Medium Material | Synthetic Fiber |

| Filtration Grade | Hepa Filter |

| Usage | HVAC System |

| Sealant | Epoxy Resin |

| Size | 2 Feet |

HEPA, which stands for High Efficiency Particulate Air, refers to a type of air filter that is designed to remove very small particles from the air. HEPA filters are commonly used in various applications to improve air quality by trapping particles like dust, pollen, pet dander, and even some bacteria and viruses. Here are some key points about HEPA filters:

Particle Removal: HEPA filters are highly effective at capturing particles as small as 0.3 microns with an efficiency of 99.97%. This includes common allergens and fine particulate matter.

Construction: HEPA filters are typically made from a dense mat of randomly arranged fiberglass fibers or other materials. These fibers create a maze-like structure that traps particles as air passes through.

Applications: HEPA filters are used in a wide range of applications, including residential air purifiers, HVAC (heating, ventilation, and air conditioning) systems, cleanrooms, hospitals, laboratories, and industrial settings where air quality is critical.

Air Purifiers: HEPA filters in air purifiers are effective at improving indoor air quality by removing allergens and pollutants. They are particularly beneficial for individuals with allergies or respiratory conditions.

Vacuum Cleaners: Some vacuum cleaners use HEPA filters to capture fine dust and allergens, preventing them from being released back into the air.

Cleanrooms: In industries like pharmaceuticals, electronics manufacturing, and biotechnology, HEPA filters are used to maintain a sterile environment by removing airborne contaminants.

Certification: To be classified as a true HEPA filter, a filter must meet specific standards and be tested and certified to have a minimum efficiency of 99.97% for particles of 0.3 microns in size. Filters that don't meet these criteria may be called HEPA-type or HEPA-style filters.

Maintenance: Regular maintenance, such as replacing or cleaning HEPA filters as recommended by the manufacturer, is essential to ensure their continued effectiveness.

HEPA filters play a vital role in improving indoor air quality and maintaining sterile environments in various industries. When selecting a HEPA filter or an appliance that uses one, it's important to check for certification and consider the specific requirements of your application.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Liquid Filter Bag, Industrial Filter |

| Width | So Many Different Sizes |

| Pattern | Plain |

| Application | Liquid Filter, Industrial Filter |

| Shape | Like Bags |

| Color | White |

| Brand Name | FILTERS23 INDIA PVT LTD, Filters23 |

| Port | SANAD |

| Payment Terms | Other |

| Delivery Time | 1-2 WEEKS |

| Packaging Details | box packing |

Liquid filter bags are a type of filtration medium used in industrial applications to remove impurities, contaminants, or particulates from liquids. They are designed to ensure clean and consistent output, maintaining the quality of processed liquids in various industries.

| Business Type | Manufacturer, Supplier |

| Color | White |

| Country of Origin | India |

| Material Grade | 140 GSM |

| Length | 100 m |

| Width | 1500 mm |

| Thickness | 2 mm |

| Applications | Air Filter |

| Material | Polyester |

Panel Filter Sheet

A panel filter sheet, also known as a panel air filter, is a type of air filter commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems to improve indoor air quality. These filters are designed to capture and remove airborne particles, dust, pollen, pet dander, and other contaminants from the air as it circulates through the system. Panel filter sheets are made of various materials, including fiberglass, polyester, or other porous materials.

Here are some key features and characteristics of panel filter sheets:

Flat Design: Panel filters are flat, rectangular or square filters that can vary in thickness. They are designed to fit into filter slots or frames within HVAC systems.

Easy Installation: They are relatively easy to install and replace, making them a popular choice for both residential and commercial applications.

Filtration Efficiency: Panel filter sheets come in different levels of filtration efficiency, typically measured by their MERV (Minimum Efficiency Reporting Value) rating. Higher MERV ratings indicate better filtration performance and the ability to capture smaller particles.

Disposable or Washable: Panel filter sheets are available in both disposable and washable varieties. Disposable filters are discarded and replaced when they become dirty, while washable filters can be cleaned and reused.

Maintenance: Regular maintenance is essential to ensure the filter continues to operate effectively. Disposable filters should be replaced according to the manufacturer's recommendations, while washable filters should be cleaned on a regular basis.

Cost-Effective: Panel filter sheets are often a cost-effective choice for basic air filtration needs, but they may not be suitable for capturing very fine particles or providing high-level filtration required in certain environments, such as hospitals or laboratories.

When selecting a panel filter sheet for your HVAC system, consider the MERV rating, the size that fits your filter slot, and whether you prefer disposable or washable options. It's important to follow the manufacturer's recommendations for maintenance and replacement to maintain good indoor air quality and the efficiency of your HVAC system.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Bag Type | Mesh Filter Bag |

| Usage/Application | Liquid Filter |

| Size | 4 x 20 inch |

| Color | White |

| Pattern | Plain |

| Material | PP |

Filter Bags

Filter Bags are cylindrical or tubular fabric-based devices used for the filtration of liquids in a wide range of industrial applications. They are an essential component of bag filter systems, which are employed to remove solid particles and contaminants from liquids. Here's an overview of filter bags, their types, materials, and common applications:

Types of Filter Bags:

Liquid Filter Bags: These are designed for the filtration of liquids, including water, oils, chemicals, and more. They are commonly used in industrial processes and various filtration systems.

Dust Collector Bags: These filter bags are used in dust collection systems to capture and contain dust and particulate matter. They are widely used in woodworking, metalworking, and other industries with dust-producing operations.

Materials for Filter Bags:

Filter bags are typically made from various materials, each suited for specific applications:

Polypropylene (PP): Commonly used for general-purpose applications, polypropylene filter bags offer good chemical resistance and are cost-effective.

Polyester (PE): Polyester bags are known for their strength, dimensional stability, and resistance to abrasion. They are often used for applications with higher operating temperatures.

Nylon (PA): Nylon filter bags are suitable for applications requiring high tensile strength and resistance to organic solvents. They are commonly used in the food and beverage industry.

PTFE (Polytetrafluoroethylene): PTFE bags are ideal for applications requiring chemical resistance to aggressive liquids and high-temperature resistance. They are commonly used in pharmaceutical and chemical industries.

Aramid (Nomex and Conex): Aramid filter bags, such as Nomex and Conex, are known for their exceptional heat resistance and are used in applications involving high-temperature gases.

Common Applications:

Filter bags find widespread use in various industries, including:

Water Treatment: Municipal and industrial water treatment plants use filter bags to remove sediment, particulates, and contaminants from water.

Oil Filtration: In the oil and gas industry, filter bags are used to filter crude oil, lubricating oils, and hydraulic fluids to remove impurities.

Chemical Processing: Chemical plants use filter bags to filter chemicals and solvents, ensuring product quality and preventing contamination.

Food and Beverage: Filter bags are used for filtering beverages like beer, wine, and fruit juices, as well as in dairy and food processing.

Pharmaceuticals: The pharmaceutical industry relies on filter bags for sterile filtration to maintain product purity.

Metalworking: In metalworking operations, filter bags in dust collection systems capture metal dust and particles to improve air quality and worker safety.

Power Generation: Power plants use filter bags for emissions control, particularly in coal-fired power plants to capture particulate matter.

Agriculture: Filter bags are used in agricultural applications to filter irrigation water and control sediment in runoff.

Chemical Manufacturing: Chemical manufacturers use filter bags to separate solids from liquid chemicals during various production processes.

Paints and Coatings: Filter bags are used to remove contaminants and ensure the quality of paints, coatings, and ink formulations.

Filter bags come in various sizes, micron ratings, and configurations to meet specific filtration requirements. Choosing the right filter bag material and design is crucial to ensure efficient and effective filtration in diverse industrial settings.

| Business Type | Manufacturer, Supplier |

| Filtration Medium Material | Fiberglass |

| Material of Construction | Aluminum |

| Filtration Grade | Pre Filter |

| Flow Rate | Customised |

| Min Working Pressure | 0.5-3 kg/cm2 |

| Filter Type | Panel Filter |

| Shape | Square |

Pre Air Filter

"pre air filter" is typically used in the context of industrial or commercial air filtration systems, particularly in settings where there is a need to capture large particles and contaminants before they reach the main air filtration system. Here are some key points about pre air filters:

Purpose: The primary purpose of a pre air filter is to act as a preliminary filter stage in an HVAC or industrial air handling system. It captures larger particles, such as dust, debris, and coarse contaminants, before the air passes through the main or final filter stage. By doing so, it helps prolong the lifespan of the main filters and improves their overall efficiency.

Construction: Pre air filters are typically constructed with a coarse filter media, often made of materials like foam, fiberglass, polyester, or metal mesh. This coarse media allows them to capture larger particles effectively while allowing relatively unrestricted airflow.

Installation: Pre air filters are usually installed upstream of the primary air filtration system. They are positioned in such a way that incoming air first passes through the pre filter, where larger particles are captured, before moving on to the main filtration stage.

Maintenance: Depending on the type of pre air filter used, maintenance can involve cleaning or replacing the filter media when it becomes clogged or too dirty to function efficiently. The maintenance frequency will vary depending on the specific application and the level of contamination in the air.

Benefits: The use of pre air filters offers several advantages, including:

Improved Main Filter Efficiency: By capturing larger particles, pre filters help extend the life of more expensive and fine-grade main filters, reducing their replacement frequency.

Reduced Maintenance Costs: Regularly replacing or cleaning pre filters is generally more cost-effective than servicing or replacing the primary filtration system.

Enhanced Air Quality: Removing larger particles at the pre filtration stage can contribute to better indoor air quality and reduce the risk of blockages or damage to HVAC equipment.

Applications: Pre air filters are commonly used in various settings, including manufacturing facilities, data centers, commercial buildings, and industries with high levels of dust, such as woodworking, metalworking, and construction.

In summary, pre air filters play a crucial role in industrial and commercial air filtration systems by capturing larger particles and contaminants before they reach the main filter stage. This helps maintain the efficiency of the entire filtration system, reduces maintenance costs, and improves indoor air quality in various applications.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Pattern | Needle Punch |

| Weight (Gram) | 100-900gm |

| Color | White |

| Width | 40 - 80 Inch |

| Length | 100 Meter |

Panel Air Filter Roll

Filters23 India "panel air filter roll" typically refers to a specific type of air filter media that comes in a roll or sheet form and is used to make custom-sized panel air filters. Panel air filters are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems to capture dust, pollen, and other airborne particles, thereby improving indoor air quality.

Here's some more information about panel air filter rolls:

Material: Panel air filter rolls are usually made from various filter media materials, including fiberglass, polyester, or other synthetic materials. The choice of material depends on the specific filtration requirements and the environment in which the filter will be used.

Customization: The roll form of these filter media allows for easy customization of filter sizes. Users can cut the filter media to the desired dimensions to fit specific air handling units or filter housings. This flexibility is especially useful when standard filter sizes are not suitable for the system.

Efficiency: The efficiency of panel air filters depends on the type and quality of the filter media used. Some panel air filter rolls are designed to provide higher filtration efficiency, capable of capturing fine particles and allergens.

Application: Panel air filter rolls are used in various HVAC systems, including residential, commercial, and industrial settings. They are often installed in filter frames or housings to remove airborne contaminants from the incoming air.

Replacement: Panel air filters need periodic replacement to maintain their effectiveness. The replacement interval depends on factors such as the level of airborne contaminants in the environment and the type of filter media used.

Disposable vs. Washable: Some panel air filter rolls are disposable, meaning they are discarded and replaced when they become clogged or inefficient. Others are washable and reusable, allowing for cleaning and reinstallation after use.

Efficiency Rating: Panel air filters may come with an efficiency rating, such as MERV (Minimum Efficiency Reporting Value) or FPR (Filter Performance Rating), which indicates their ability to capture different sizes of particles.

Maintenance: Regular maintenance, including cleaning or replacing the filter media, is crucial to ensure the HVAC system operates efficiently and maintains good indoor air quality.

When using a panel air filter roll, it's important to follow the manufacturer's guidelines for installation, maintenance, and replacement to ensure optimal filtration performance. Properly maintained panel air filters can help extend the life of HVAC equipment, reduce energy consumption, and provide cleaner and healthier indoor air.