| Business Type | Manufacturer, Supplier |

| Color | White, Yellow |

| Condition | New |

| Pattern | Plain |

| Click to view more | |

Product Details

Industries and applications to improve air quality and reduce airborne dust and particulate matter. These bags are designed to capture and filter out fine dust and particles from the air, preventing them from being released into the environment or workplace.

Here are some key features and information about dust collector filter bags:

Material: Dust A dust collector filter bag is an essential component of a dust collection system used in various collector filter bags are typically made from various materials, including polyester, polypropylene, fiberglass, and other synthetic or natural fibers. The choice of material depends on the specific application and the type of dust or particles being captured.

Filtration Efficiency: Filter bags are designed to have a high filtration efficiency, meaning they can capture a significant percentage of particles of a certain size or smaller. The filtration efficiency is often measured using standards such as the MERV (Minimum Efficiency Reporting Value) rating or the HEPA (High-Efficiency Particulate Air) classification for very fine particles.

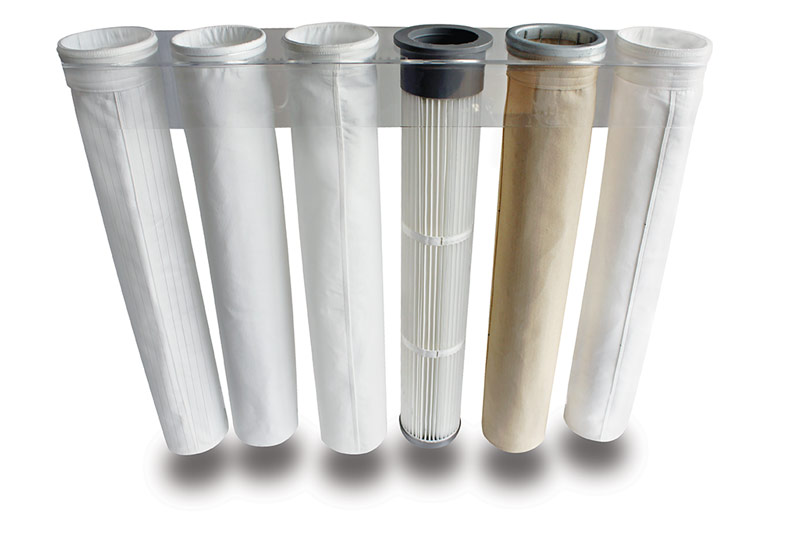

Bag Design: Dust collector filter bags come in various designs, including tubular bags, envelope bags, and pleated bags. The design affects the surface area available for filtration and can impact the overall efficiency and longevity of the filter.

Size and Dimensions: The size and dimensions of filter bags can vary widely to fit different types and sizes of dust collectors and dust collection systems. It's essential to choose the right size and style of filter bag for your specific dust collection equipment.

Dust Collector Type: Filter bags are used in various types of dust collectors, including baghouses, cartridge collectors, and pulse jet collectors. The type of collector will dictate the appropriate filter bag design and material.

Maintenance and Replacement: Dust collector filter bags require regular maintenance and periodic replacement to maintain optimal performance. Over time, dust accumulation can reduce airflow and filtration efficiency, so it's crucial to follow a maintenance schedule and replace filter bags as needed.

Application: Dust collector filter bags are used in a wide range of industries and applications, including woodworking, metalworking, pharmaceuticals, food processing, cement manufacturing, and many others where dust and particulate matter are generated.

Proper selection, installation, and maintenance of dust collector filter bags are essential to ensure that they effectively capture and contain dust and particulate matter, protecting the environment and worker health. Additionally, it helps maintain the efficiency of the dust collection system and extends the life of the equipment.

dust collector filter cage

A dust collector filter cage is an essential component within a dust collector system, specifically designed to support and maintain the shape and structure of filter bags or filter cartridges. These cages play a critical role in ensuring the efficient operation of dust collectors by preventing filter bags or cartridges from collapsing or sagging under the influence of airflow and the weight of accumulated dust.

Here are some key features and information about dust collector filter cages:

Material: Filter cages are typically constructed from various materials, including carbon steel, stainless steel, or galvanized steel. The choice of material depends on factors such as the environment in which the dust collector operates and the type of dust or particulates being filtered.

Design: Filter cages come in various designs, such as round, oval, or star-shaped configurations. The design is often selected based on the shape and size of the filter bags or cartridges they support.

Size and Dimensions: Filter cages are available in a range of sizes and dimensions to accommodate different filter bag or cartridge sizes and styles. They are custom-fitted to match the specific requirements of the dust collector system.

Installation: Filter cages are installed inside the filter bags or cartridges before they are placed within the dust collector housing. Proper installation ensures that the filter bags or cartridges maintain their shape and do not collapse during operation.

Function: The primary function of a filter cage is to provide structural support to the filter media (bag or cartridge) while allowing air to pass through and be filtered. It prevents filter media from collapsing under the pressure of airflow and the weight of accumulated dust, which could lead to reduced filtration efficiency and increased maintenance needs.

Maintenance: Filter cages typically require minimal maintenance. However, they should be periodically inspected for damage or wear, and any damaged cages should be replaced promptly to ensure the continued efficiency of the dust collector.

Compatibility: It's essential to choose filter cages that are compatible with the specific type and design of filter bags or cartridges used in your dust collector system. Compatibility ensures proper fit and function.

Dust collector filter cages are crucial components of dust collection systems, helping to maintain consistent filtration performance and extending the lifespan of filter media. They are commonly used in various industries where dust and particulate matter need to be captured and removed from the air to improve air quality and protect worker health.

Looking for "Dust Collector Filter Bag" ?

Explore More Products