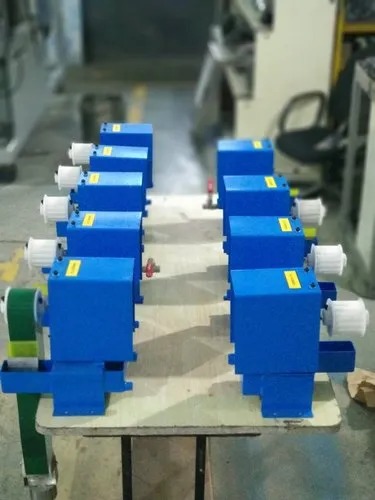

Oil Skimmer

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Belt Type Oil Skimmer, CNC Oil Skimmer, Disc Type Oil Skimmer, Portable Oil Skimmer, Portable Oil Skimmer For CNC, Square Tramp Oil Separator, Tramp Oil Separator and Tube Type Oil Skimmers from Mulchand.

| Business Type | Manufacturer, Supplier |

| Material | Stainless Steel |

| Country of Origin | India |

| Capacity | 55 LPH |

| Type Of Machine | Oil Skimmer |

| Type | Belt type |

| Usage/Application | Industrial |

| Surface Finish | Power Coated |

| Frequency | 50 Hz |

| Power Supply | Electric |

| Power Source | Single Phase |

| Voltage | 240V |

Belt Type Oil Skimmer

FILTERS23 INDIA`S Belt type oil skimmer is a mechanical device used for removing oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water or other liquids. These skimmers are often employed in industrial and environmental applications to effectively separate and collect oil and grease contaminants from water bodies, process tanks, or other liquid surfaces. Here's how a belt type oil skimmer typically works and some key features:

Working Principle:

Endless Belt: A belt type oil skimmer consists of an endless loop of belt or a similar material. The belt is typically made of materials that repel water but attract oil, such as oleophilic (oil-attracting) materials.

Deployment: The skimmer deploys the belt into the liquid to be skimmed. The belt floats on the surface of the liquid, and a portion of it is submerged.

Surface Contact: As the belt travels along the liquid's surface, it comes into contact with the oil or grease on the surface. Due to its oil-attracting properties, the belt adheres to the oil, and the oil sticks to the belt's surface.

Oil Removal: The belt continues to move, carrying the adhered oil away from the liquid's surface. As it moves, the belt passes through a scraper or wiper mechanism that removes the oil from the belt's surface.

Collection: The collected oil is typically directed into a separate collection container or storage tank. The collected oil can then be periodically removed for disposal or recycling.

Key Features:

Adjustable Speed: Many belt type oil skimmers feature adjustable speed controls, allowing operators to regulate the skimming rate based on the application's specific requirements and the volume of oil to be removed.

Self-Adjusting: These skimmers are designed to automatically adjust to changes in the liquid level, ensuring efficient oil removal even if the liquid level fluctuates.

Efficiency: Belt type oil skimmers are known for their high efficiency in removing oil and grease from water or other liquids. They can effectively remove both thin sheens of oil and thicker layers of oil.

Low Maintenance: They typically require minimal maintenance, with routine cleaning and occasional replacement of wear parts being the primary maintenance tasks.

Versatility: Belt type oil skimmers can be used in a wide range of environments, including industrial wastewater treatment, oil spill response, coolant recycling, and other applications where oil-water separation is necessary.

Compact Design: Their compact and portable design makes them suitable for various settings and locations.

Environmental Benefits: By removing oil and grease from water bodies, belt type oil skimmers help protect the environment by preventing the contamination of natural water sources.

Belt type oil skimmers are valuable tools for industries dealing with oily wastewater or encountering oil contamination problems. Their efficient and reliable operation contributes to cleaner and more environmentally friendly water management by effectively separating and collecting oil and grease contaminants.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | BELT TYPE OIL SKIMMER |

| Certification | ISO |

| Application | INDUSTRIAL |

| Finishing | Polished |

| Material | Stainless Steel |

| Brand Name | FILTERS23 INDIA PVT LTD |

| Warranty | 1 YEAR |

| Port | SANAD |

| Payment Terms | L/C, D/A |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | WOODEN BOX |

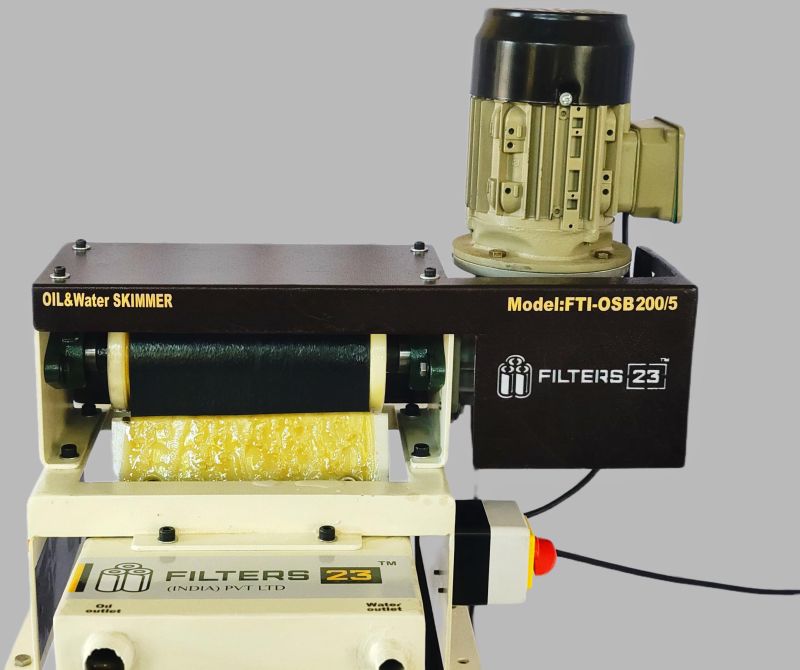

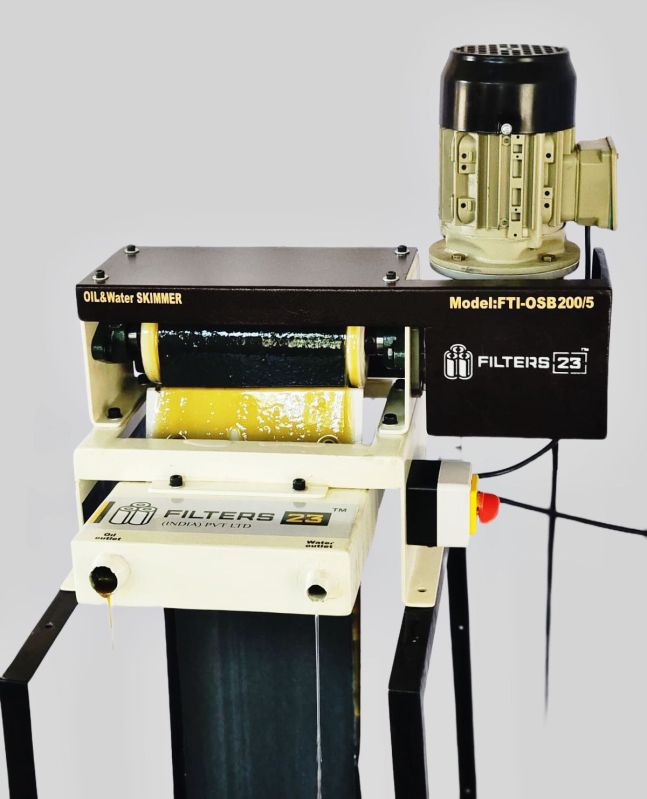

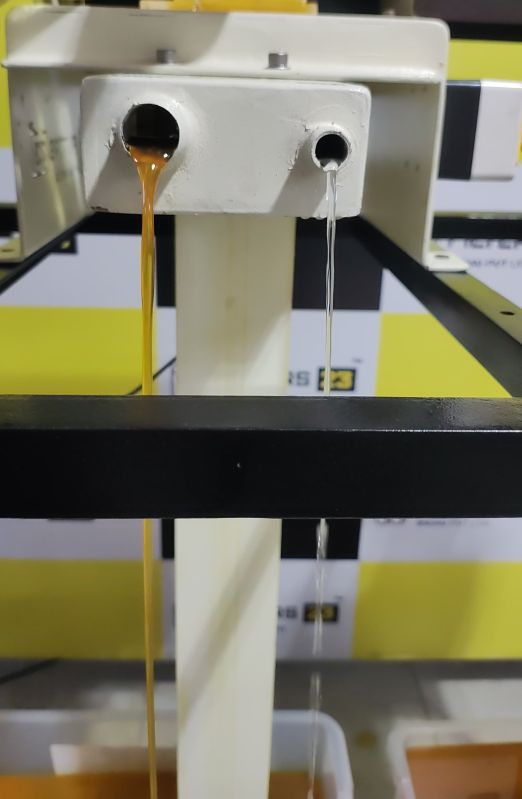

Oil & Water Skimmer by Filters 23 (India) Pvt Ltd is an efficient and reliable solution designed to separate oil from water in industrial and commercial applications. This advanced skimming system is engineered to ensure optimal performance and durability, catering to various industries where oil-water separation is critical.

Features

1. Efficient Separation: The skimmer effectively separates oil from water, ensuring clean water discharge and proper oil recovery.

2. Robust Design: Constructed with high-quality materials to withstand harsh industrial environments and ensure long-lasting performance.

3. Model Specification:

We have basic Model start from 50 MM wide belt to 500 MM wide belt

And length of belt accordingly Tank depth

4. User-Friendly Operation: Easy to operate with minimal maintenance requirements, making it suitable for continuous operation.

6. High-Capacity Skimming: Capable of handling large volumes of oil-water mixtures, making it ideal for high-demand applications.

-

Applications

- Manufacturing: Removing oil from coolant systems, parts washers, and other machinery.

- Automotive: Skimming oil from wash tanks, rinse tanks, and engine cleaning processes.

- Food Processing: Ensuring oil-free water in food processing and preparation areas.

- Wastewater Treatment: Enhancing the efficiency of wastewater treatment plants by pre-separating oil from water.

- Marine: Used on ships and boats to separate oil from bilge water, preventing environmental pollution.

STP, ETP Plants

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Frequency | 50 Hz |

| Phase | Single Phase |

| Voltage | 220V AC |

| Power | 25W |

| Available Depth | 100 mm, 140 mm |

| Available Capacity | 6 L/H, 8-10 L/H |

| Available Material of Disc | SS304, PU Belt |

| Available Disc Diameter | 320mm, 450mm |

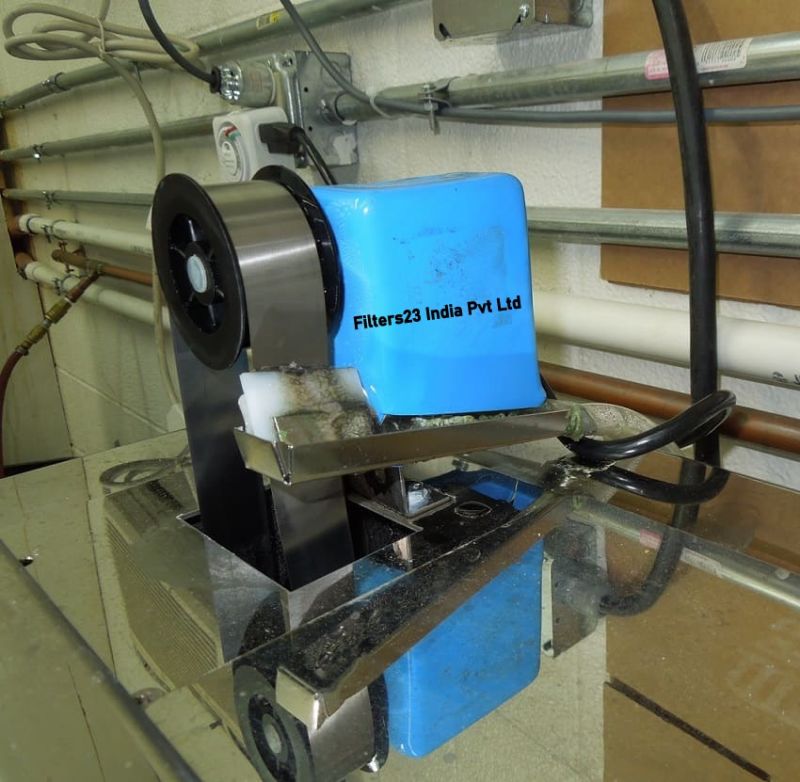

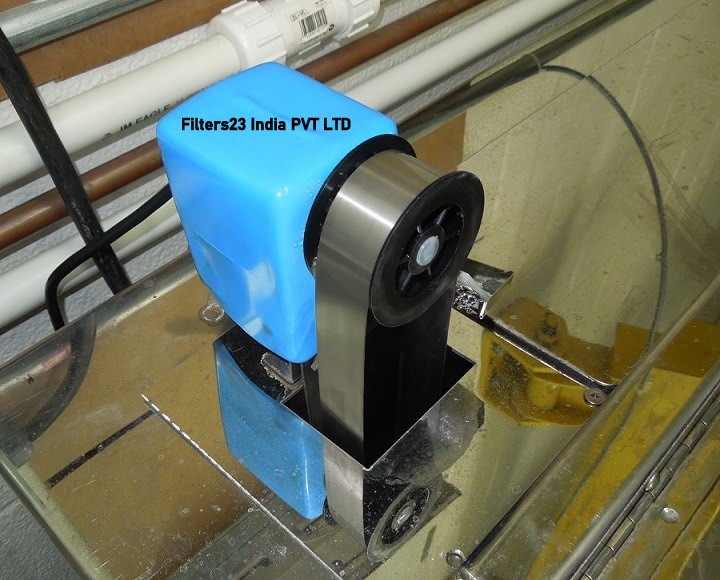

Disc Type Oil Skimmer

A disc type oil skimmer is a mechanical device designed to remove oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water or other fluids. These skimmers are commonly used in industrial and environmental applications to separate and collect oil and grease contaminants from water bodies, process tanks, or other liquid surfaces. Here's how a disc type oil skimmer typically works and its key features:

Working Principle:

Floating Discs: A disc type oil skimmer consists of one or more floating discs or wheels that are partially submerged in the liquid. These discs are typically made of materials that repel water but attract oil, such as oleophilic (oil-attracting) materials or materials with low surface tension.

Rotation: The floating discs are set in motion, often driven by an electric motor. As they rotate, they come into contact with the surface of the liquid.

Oil Attraction: The hydrophobic discs have a natural affinity for oil and grease, causing them to pick up a thin layer of these contaminants as they make contact with the liquid surface. The oil adheres to the surface of the discs.

Scraping Mechanism: As the discs continue to rotate, a scraper mechanism or wiper removes the collected oil from the disc's surface. The oil is then directed into a collection container or storage tank.

Continuous Operation: The process is continuous, with the oil skimmer continuously collecting oil from the liquid surface as long as it remains in operation. The collected oil can be periodically removed from the collection container for disposal or recycling.

Key Features:

Variable Speed: Many disc type oil skimmers have adjustable speed controls, allowing operators to fine-tune the skimming process based on the specific application and the amount of oil to be removed.

Self-Adjusting: These skimmers are often designed to automatically adjust to changes in the liquid level, ensuring consistent and efficient oil removal even as the liquid level fluctuates.

Efficiency: Disc type oil skimmers are known for their high efficiency in removing oil and grease from water or other fluids. They can effectively remove both thin sheens of oil and thicker layers of oil.

Low Maintenance: They typically require minimal maintenance, with routine cleaning and occasional replacement of wear parts as the primary maintenance tasks.

Versatility: Disc type oil skimmers can be used in a wide range of environments, including industrial wastewater treatment, oil spill response, coolant recycling, and other applications where oil-water separation is necessary.

Compact Design: Their compact and portable design makes them suitable for use in various settings and locations.

Environmental Benefits: By removing oil and grease from water bodies, disc type oil skimmers contribute to environmental protection by preventing the contamination of natural water sources.

Disc type oil skimmers are valuable tools for industries that deal with oily wastewater or encounter oil contamination issues. Their efficient and reliable operation helps ensure the separation and removal of oil and grease, contributing to cleaner and more environmentally friendly water management.

| Business Type | Manufacturer, Supplier |

| Finishing | Polished |

| Application | Industrial Use |

| Type | Oil Separator |

| Country of Origin | India |

| Feature | 5 LPH TO 320 LPH |

| Capacity | Industrial |

| Motor Rating | 05 Hp, 1.0 Hp, 1.5 Hp, 2.0 Hp Etc |

Oil Skimmers

FILTERS23 INDIA`S Belt type oil skimmer is a mechanical device used for removing oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water or other liquids. These skimmers are often employed in industrial and environmental applications to effectively separate and collect oil and grease contaminants from water bodies, process tanks, or other liquid surfaces. Here's how a belt type oil skimmer typically works and some key features:

Working Principle:

Endless Belt: A belt type oil skimmer consists of an endless loop of belt or a similar material. The belt is typically made of materials that repel water but attract oil, such as oleophilic (oil-attracting) materials.

Deployment: The skimmer deploys the belt into the liquid to be skimmed. The belt floats on the surface of the liquid, and a portion of it is submerged.

Surface Contact: As the belt travels along the liquid's surface, it comes into contact with the oil or grease on the surface. Due to its oil-attracting properties, the belt adheres to the oil, and the oil sticks to the belt's surface.

Oil Removal: The belt continues to move, carrying the adhered oil away from the liquid's surface. As it moves, the belt passes through a scraper or wiper mechanism that removes the oil from the belt's surface.

Collection: The collected oil is typically directed into a separate collection container or storage tank. The collected oil can then be periodically removed for disposal or recycling.

Key Features:

Adjustable Speed: Many belt type oil skimmers feature adjustable speed controls, allowing operators to regulate the skimming rate based on the application's specific requirements and the volume of oil to be removed.

Self-Adjusting: These skimmers are designed to automatically adjust to changes in the liquid level, ensuring efficient oil removal even if the liquid level fluctuates.

Efficiency: Belt type oil skimmers are known for their high efficiency in removing oil and grease from water or other liquids. They can effectively remove both thin sheens of oil and thicker layers of oil.

Low Maintenance: They typically require minimal maintenance, with routine cleaning and occasional replacement of wear parts being the primary maintenance tasks.

Versatility: Belt type oil skimmers can be used in a wide range of environments, including industrial wastewater treatment, oil spill response, coolant recycling, and other applications where oil-water separation is necessary.

Compact Design: Their compact and portable design makes them suitable for various settings and locations.

Environmental Benefits: By removing oil and grease from water bodies, belt type oil skimmers help protect the environment by preventing the contamination of natural water sources.

Belt type oil skimmers are valuable tools for industries dealing with oily wastewater or encountering oil contamination problems. Their efficient and reliable operation contributes to cleaner and more environmentally friendly water management by effectively separating and collecting oil and grease contaminants.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Belt Type |

| Application | Oil Removing |

| Finishing | Polished |

| Material | Mild Steel |

| Design | Portable |

| Capacity | 0-2 LPH |

| Width of Belt | 60 mm |

| Frequency | 50/60 Hz |

| Phase | Single Phase |

| Power Source | Electric |

| Belt Width | 50 mm |

| Power | 25W |

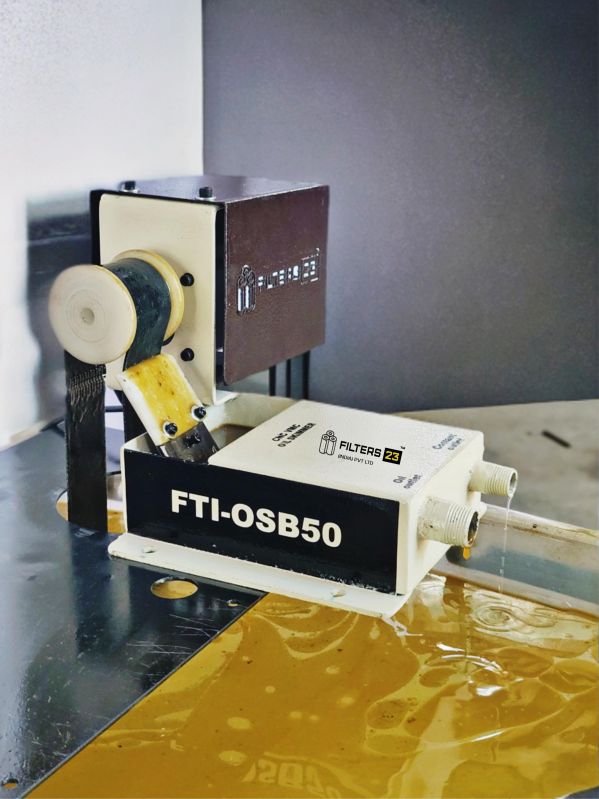

CNC Tank Oil Skimmers

FILTERS23 INDIA Designed small belt-type oil skimmer is a device designed to remove oil and other hydrophobic liquids from the surface of water or other liquids. It's commonly used in industrial and environmental applications to prevent oil contamination in bodies of water, such as ponds, lakes, or industrial tanks. Here are some details about small belt-type oil skimmers:

Basic Principle: Small belt-type oil skimmers work on the principle of utilizing a moving belt to pick up oil or other floating contaminants from the surface of water. The belt is specially designed to attract and collect oils and grease while repelling water.

Components: A typical small belt-type oil skimmer consists of the following components:

Belt: The heart of the skimmer is the continuous loop of material, usually made of materials like oleophilic (oil-attracting) material or synthetic materials specifically designed for this purpose.

Wiper Blades: To effectively remove collected oil from the belt, wiper blades or scrapers are employed. These blades scrape the oil off the belt into a collection container.

Oil Collection Container: The collected oil is deposited into a separate container, which can be easily removed and emptied.

Installation: Small belt-type oil skimmers can be installed in various settings, including wastewater treatment plants, industrial sumps, coolant tanks, and bodies of water. They are typically mounted on the edge of the liquid, and the skimming depth can be adjusted to match the specific application.

Applications:

Industrial Facilities: Used to remove oil and grease from coolant tanks, parts washers, and wastewater treatment processes.

Environmental Remediation: Applied in spill response and cleanup operations to remove oil from water bodies.

Marine Industry: Utilized on ships and offshore platforms to collect oil spills.

Food Processing: Helps in removing oils and fats from food processing wastewater.

Maintenance: Small belt-type oil skimmers are generally low-maintenance devices. Routine maintenance involves checking the belt for wear and tear, inspecting the motor and drive mechanism, and emptying the oil collection container when it fills up.

Benefits:

Efficient at removing floating oil and contaminants from the liquid surface.

Cost-effective and relatively low-maintenance.

Helps in compliance with environmental regulations.

Reduces the need for chemical treatments to remove oil from water.

Limitations:

Works best with liquid surfaces that are relatively calm, as waves or turbulence can disrupt skimming efficiency.

May not be suitable for very thick or viscous oils.

Requires a power source for the motor.

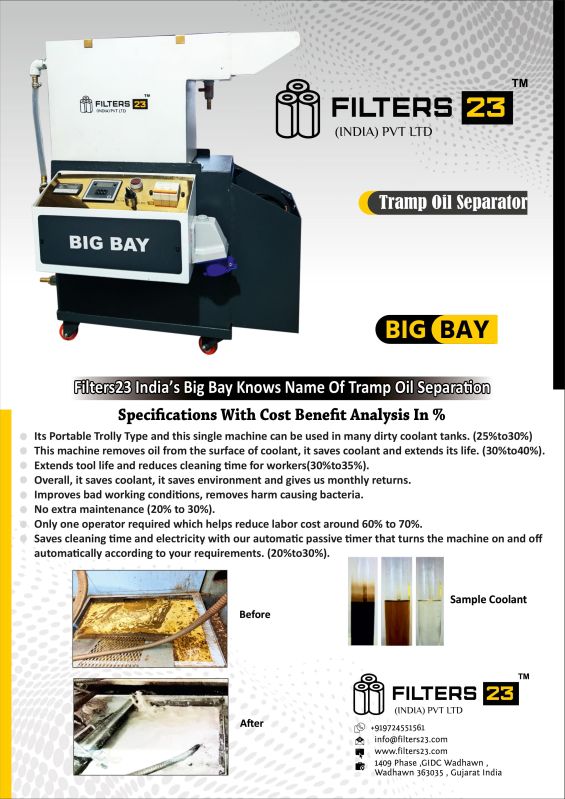

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Capacity | Upto 500 LPH |

| Model Name/Number | TOT-500 |

| Type of Machine | Portable |

| Shape | Square |

| Material | MS/SS |

| Max Working Pressue | 4-5 kg/cm2 |

| Business Type | Manufacturer, Supplier |

| Application | Industrial Use |

| Power Consumption | 0.4 kWh |

| Voltage | 240 VAC |

| Pipe Dimensions | Diameter 32 mm |

| Timer Settings | 0 - 99 Hrs ON,0- 99 Hrs OFF (Available in KTEC mini) |

| Material | MS/SS |

| Max Working Pressue | 4-5 kg/cm2 |

Big Bay (tramp oil separator)

Filters23 India Pvt Ltd `s tramp oil separator, also known as an oil skimmer or oil separator, is a device used in industrial settings to remove unwanted oils, such as tramp oil, from coolant or wastewater. Tramp oil is oil that contaminates machine coolant, typically in metalworking or machining processes. It can come from various sources, including leaking hydraulic systems, lubricants, or residues from machining operations. Removing tramp oil is essential to maintain the quality and effectiveness of coolants and prevent issues like bacterial growth, reduced tool life, and poor surface finish in machining operations.

Here's how a tramp oil separator typically works:

Skimming Mechanism: Tramp oil separators are equipped with a skimming mechanism that comes into contact with the contaminated liquid. The skimming mechanism is designed to be selective, picking up and removing the floating tramp oil while leaving the coolant or wastewater behind.

Floating Oil Collection: As the skimming mechanism operates, it collects the tramp oil that naturally floats on the surface of the liquid. This oil can be in the form of a thin film or droplets.

Separation: Once collected, the tramp oil is separated from the liquid coolant or wastewater. This separation can occur through various means, depending on the design of the tramp oil separator. Common separation methods include gravity separation, coalescence, or the use of special materials that repel water but attract oil.

Oil Collection and Disposal: The separated tramp oil is typically directed into a collection container or reservoir for later disposal or recycling. Some tramp oil separators can automatically pump the collected oil to a separate storage tank.

Cleaned Liquid: The cleaned coolant or wastewater, now free of tramp oil, can be returned to the machining process or discharged as needed.

Key features and benefits of tramp oil separators include:

Improved Coolant Quality: By removing tramp oil, these separators help maintain the integrity of coolant, which is critical for machining processes' performance and tool life.

Reduced Environmental Impact: Proper disposal or recycling of the collected tramp oil minimizes environmental contamination.

Cost Savings: Longer coolant life and reduced tool wear translate into cost savings for maintenance and replacement.

Ease of Maintenance: Tramp oil separators are generally easy to maintain, with minimal downtime for cleaning and servicing.

Tramp oil separators come in various sizes and configurations to suit different industrial applications and coolant systems. The choice of a specific tramp oil separator depends on factors such as the volume of coolant, type of contaminants, and the desired level of automation for oil removal.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Capacity | 100-135 LPH |

| Pulley Speed | 30 rpm |

| Tube Dia | 18 mm |

| Tube Speed | 17 Metres Per Minute |

| Type | Tube type |

| Usage/Application | Oil Removing |

| Oil Recycle Rate | 1000 (l/hr) |

Tube type oil skimmers

Filters23 India Tube type oil skimmers are mechanical devices used to remove oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water, coolant tanks, process tanks, or other liquid surfaces. These skimmers operate on the principle of using a floating tube or hose that attracts and collects the oil. Here's how tube type oil skimmers work and some key features:

Working Principle:

Floating Tube: Tube type oil skimmers consist of a floating tube or hose made from a material that is oleophilic (oil-attracting) but hydrophobic (water-repellent). This means that the tube has an affinity for oil but repels water.

Deployment: The skimmer deploys the floating tube onto the liquid surface. The tube is positioned so that it floats and remains partially submerged in the liquid, allowing it to come into contact with the oil layer on the surface.

Oil Adhesion: As the floating tube moves along the liquid's surface, it naturally attracts and adheres to the oil. The hydrophobic nature of the tube ensures that it repels water and selectively captures the oil.

Tube Rotation: The floating tube is typically wound around a motor-driven drum or pulley mechanism. As the tube is wound around the drum, it collects the adhered oil along its surface.

Oil Collection: As the tube is drawn onto the drum, the oil adhering to it is scraped off and collected. The collected oil is often directed into a separate collection container or storage tank for further processing or disposal.

Key Features:

Self-Adjusting: Tube type oil skimmers are designed to automatically adjust to changes in the liquid level, ensuring efficient oil removal even when the liquid level fluctuates.

Efficiency: They are known for their high efficiency in removing oil and grease from water or other liquids, making them suitable for applications with varying levels of oil contamination.

Low Maintenance: Tube type oil skimmers typically require minimal maintenance, with routine cleaning of the tube and occasional replacement of wear parts being the primary maintenance tasks.

Versatility: They can be used in various environments and industries, including machining operations, wastewater treatment, oil storage tanks, and industrial process tanks.

Compact Design: Their compact and portable design makes them suitable for various settings and locations.

Environmental Benefits: By effectively removing oil and grease from water bodies, tube type oil skimmers help protect the environment by preventing the contamination of natural water sources.

Tube type oil skimmers are valuable tools for industries dealing with oily wastewater or encountering oil contamination issues. Their efficient and reliable operation contributes to cleaner and more environmentally friendly liquid management by effectively separating and collecting oil and grease contaminants.