Filter Paper Rolls

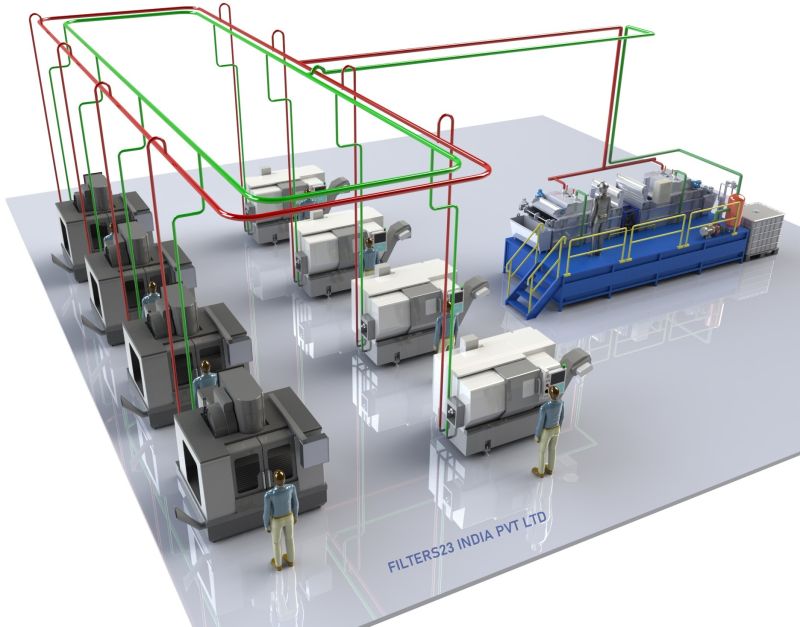

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Centralized Filtration Paper Rolls, Compact Band Filter Paper Roll, Coolant Filter Paper Roll, Cutting Oil Filter Rolls, Grinding Machine Coolant Filter Paper Roll, Honing Oil Filter Paper Roll, Hot Oil Filter Paper, Industrial Filter Paper Roll, Micron Coolant Filter Paper Roll, Needle Punch Filter Paper Roll and Oil Filter Paper Roll from Mulchand.

| Business Type | Manufacturer, Exporter |

| Brand Name | FILTERS23,FILTERS23 |

| Material | FILTER PAPER |

| Color | White |

| Application | INDUSTRIAL |

| Certification | ISO 9001:2008, CE Certified |

| Type | CENTRALIZED FILTER PAPER ROLL |

| Country of Origin | India |

| Warranty | 1 YEAR |

| Port | SANAD |

| Payment Terms | D/A, Other |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | BUNDLE |

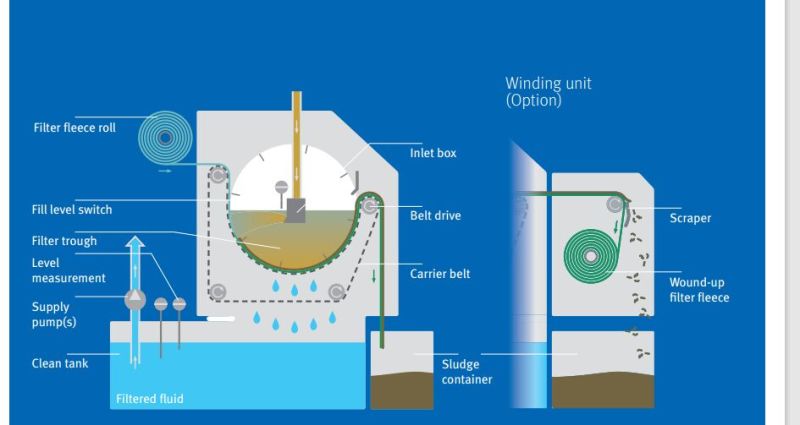

Centralized filtration paper rolls often use filter paper rolls as a common filtration medium to remove impurities, contaminants, and particulate matter from fluids. These systems are commonly employed in various applications, including industrial processes, municipal water treatment, and other large-scale filtration needs. Here's how centralized filtration systems typically use filter paper rolls: 1. Filtration Media Selection: In a centralized filtration system, the choice of filter paper roll is critical. Filter paper rolls are selected based on the specific requirements of the application, including the type of fluid being filtered, the size and nature of contaminants, and the desired filtration efficiency. The filter paper roll should have an appropriate filtration rating measured in microns to effectively capture the desired particle sizes. 2. Fluid Circulation: The fluid to be filtered is circulated through the filtration system. In the case of water treatment plants, for example, raw water enters the system and passes through the filter paper roll to remove impurities and contaminants. In industrial processes, the fluid may be a coolant, hydraulic fluid, or another liquid requiring filtration. Filtration Rating: A micron (µm) is a unit of measurement equal to one-thousandth of a millimeter (0.001 mm). Micron filter paper is rated based on the size of particles it can retain. For example, a 10-micron filter paper can capture particles that are 10 micrometers or larger in size. Filter Material: Micron filter paper is typically made from cellulose or synthetic fibers. The choice of material depends on factors like compatibility with the fluid being filtered, the required filtration efficiency, and the operating conditions (temperature, chemical resistance). Filtration Process: When a fluid passes through micron filter paper, the filter media traps and retains particles that are larger than the rated micron size. Smaller particles that are below the specified micron rating will pass through the filter. Common Applications: Water Filtration: Micron filter paper is used in various water treatment applications to remove suspended solids, sediments, and particulate matter from drinking water, wastewater, and industrial process water. Industrial Filtration: In industrial processes, micron filter paper is used to filter liquids such as hydraulic fluids, lubricants, cutting fluids, and coolant fluids. It helps maintain the quality of these fluids by removing contaminants that could damage equipment or reduce performance. Pharmaceuticals: Micron filter paper is used in pharmaceutical manufacturing for sterile filtration, ensuring that liquids and solutions are free from particulate matter and microorganisms. Food and Beverage: It is used in the food and beverage industry to clarify liquids such as fruit juices, edible oils, and wine, ensuring they meet quality standards. Automotive: Micron filter paper is used in automotive filters, including oil filters and fuel filters, to remove particles and contaminants from engine fluids. Filter Selection: Choosing the right micron rating for filter paper depends on the specific application and the desired level of filtration. Finer micron ratings are used when high purity is required, while larger micron ratings are suitable for removing larger particles. Maintenance: Regular maintenance is necessary to ensure that the filter paper remains effective. As the filter accumulates contaminants, it may need to be replaced or cleaned, depending on the filtration system and the application. Filter Configuration: Micron filter paper can be found in various forms, including filter rolls, filter sheets, and filter cartridges, to accommodate different filtration equipment and systems. Micron filter paper is a versatile filtration medium that plays a critical role in ensuring the quality and purity of fluids in various industries and applications.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Material Grade | 20 GSM |

| Material | Non Woven |

| Length | Upto 150 Meter |

| Width | 50 mm |

| Usage | For Filtration |

| Thickness | Upto 10 mm |

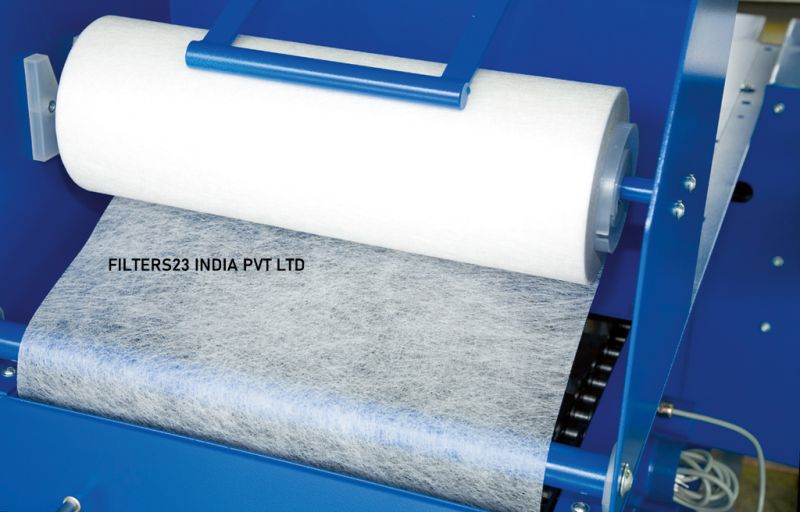

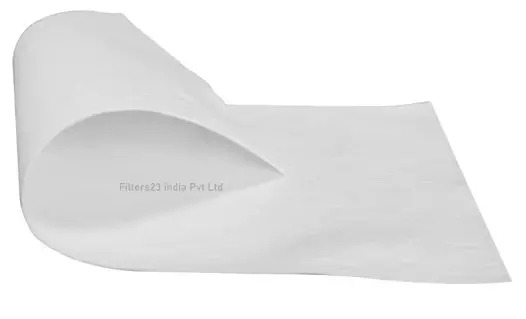

Compact Band Filter Paper Roll

Filters23 india`s "compact band filter paper roll" likely refers to a specific type of filter media or filter roll used in compact or space-efficient band filtration systems. While I don't have access to specific product names or models beyond my knowledge cutoff date in September 2021, I can provide some general information about compact band filter paper rolls and their possible applications:

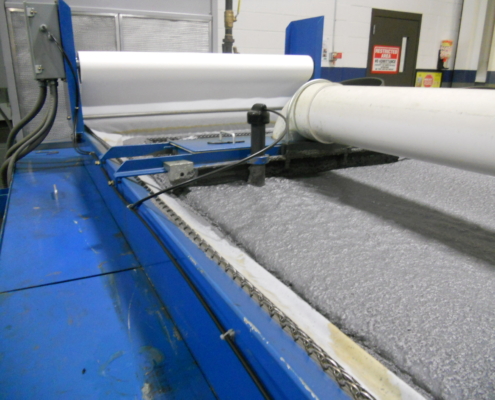

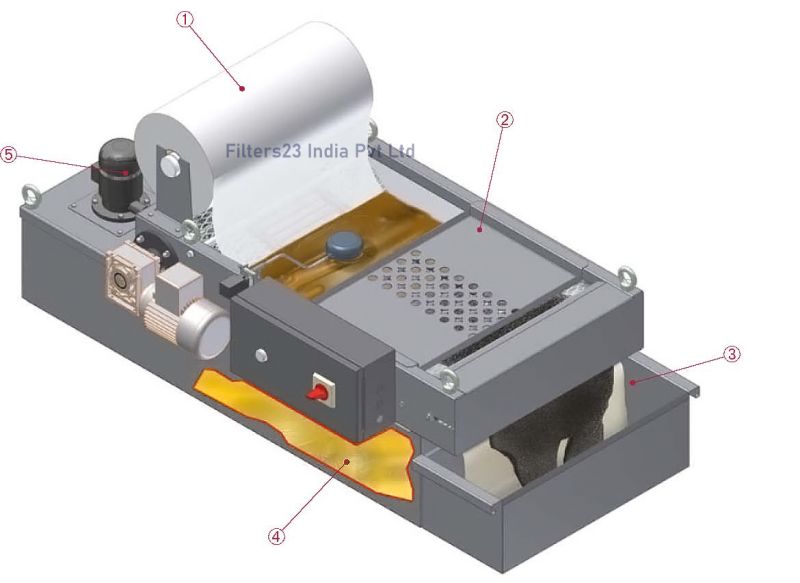

Compact Band Filtration Systems: Compact band filtration systems are designed to provide effective filtration in applications where space constraints or a compact design is essential. These systems are often used in industrial processes, including metalworking, machining, and other applications where cutting fluids or coolants need to be filtered to remove contaminants and extend their usability.

Filter Media Characteristics:

Filtration Rating: Like standard filter paper rolls, compact band filter paper rolls are available in various filtration ratings, typically measured in microns. The choice of filtration rating depends on the specific application and the desired level of filtration.

Material: These rolls are typically made from specialized filter paper or fabric materials that offer high particle retention capabilities and compatibility with the cutting fluids or coolants used in machining processes.

Roll Format: Compact band filter paper rolls are designed to fit into space-efficient filter units or systems. The rolls come in continuous roll form, allowing users to cut the material to the required length to fit their compact filtration equipment. The rolls may have varying widths and lengths to accommodate different filter systems.

Benefits:

Compact band filtration systems offer the same advantages as traditional band filtration systems, including improved machining performance, cost savings through extended cutting fluid life, and reduced environmental impact by minimizing fluid disposal.

Maintenance and Replacement:

Regular maintenance and replacement of the compact band filter paper roll are necessary to ensure consistent filtration efficiency and prevent the buildup of contaminants in the machining process.

| Business Type | Manufacturer, Supplier |

| Color | White |

| Feature | Premium Quality |

| Pattern | Plain |

| Type | Paper Rolls |

| Country of Origin | Made In India |

| Material | Viscose |

| Usage/Application | Coolant |

| GSM | 550 |

| Micron Ratings | 5 Micron |

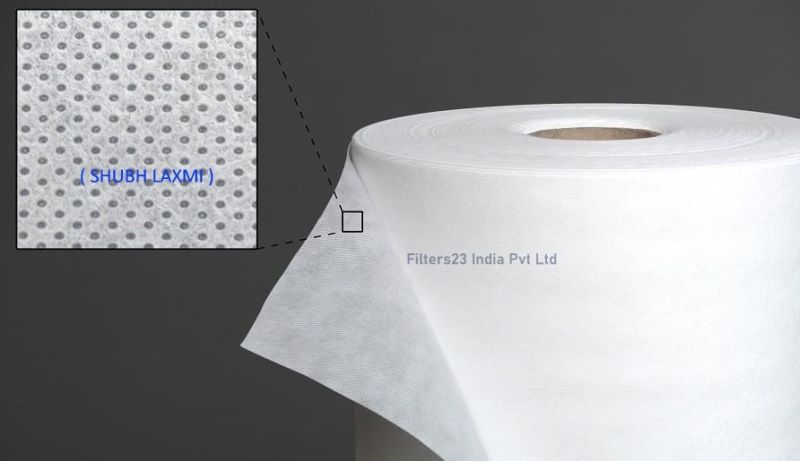

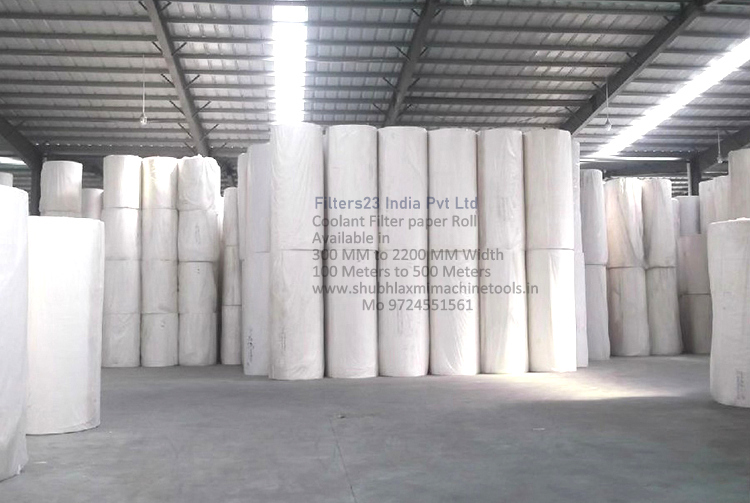

Coolant filter paper rolls

Coolant filter paper rolls, also known as filter media rolls or filter paper rolls, are commonly used in industrial settings to filter and purify cutting fluids, coolants, and lubricants used in machining, metalworking, and other industrial processes. These filter rolls help remove particulates, contaminants, and debris from the fluids, ensuring the longevity and efficiency of equipment and tools. Here are some key features and uses of coolant filter paper rolls:

Material: Coolant filter paper rolls are typically made from specialized filter media designed to effectively capture and retain solid particles, metal shavings, and other contaminants without breaking down when exposed to coolants or cutting fluids.

Filtration Efficiency: The choice of filter paper roll depends on the desired level of filtration efficiency. Various roll grades with different particle size retention capabilities are available to suit specific applications.

Continuous Filtration: These rolls are often used with industrial filtration systems, such as gravity bed filters, vacuum filters, or other custom filter setups, to provide continuous filtration of coolant or cutting fluids.

Versatility: Coolant filter paper rolls can be used with various types of coolants and cutting fluids, including water-based and oil-based fluids, to maintain fluid quality and extend their usable life.

Cost Reduction: Proper filtration with these rolls can significantly reduce the frequency of coolant or cutting fluid replacement, resulting in cost savings for industrial operations.

Tool and Equipment Protection: By removing contaminants and debris from the coolant or cutting fluid, filter paper rolls help protect machining tools and equipment, extending their lifespan and reducing maintenance costs.

Improved Surface Finish: Cleaner fluids with reduced contamination levels can lead to improved surface finish and precision in machining processes.

Environmental Considerations: Effective filtration not only benefits equipment but also reduces waste and disposal costs associated with spent coolant or cutting fluids.

Safety and Worker Health: Maintaining clean and uncontaminated coolants and cutting fluids promotes a safer working environment and reduces health risks for workers exposed to these fluids.

Custom Sizing: Coolant filter paper rolls come in various widths and lengths to accommodate different filtration systems and industrial applications. They can be cut to size as needed.

Regular maintenance and replacement of coolant filter paper rolls are essential to ensure consistent filtration performance and prevent clogging. Proper filtration contributes to the overall efficiency and cost-effectiveness of industrial processes by extending the usable life of coolants and cutting fluids and protecting valuable equipment

| Business Type | Manufacturer, Supplier |

| Color | White |

| Condition | New |

| Feature | Durable, Perfect Filtration |

| Type | Cutting Oil Filter |

| Country of Origin | India |

| Material Grade | 40 GSM |

| Length | 100 m |

| Width | 2000 mm |

| Thickness | 0.7 mm |

| Micron Ratings | 5 Micron |

| GSM | 30 To 120GSM |

Cutting oil filter paper rolls

Cutting oil filter paper rolls, also known as filter media rolls or filter paper rolls, are specialized filter materials used in industrial applications to filter and purify cutting oils, coolants, and lubricants used in machining and metalworking processes. These filter rolls are designed to remove particulates, metal shavings, contaminants, and debris from the cutting fluids, helping to maintain the quality and longevity of the fluids and the efficiency of the machining equipment. Here are some key features and applications of cutting oil filter paper rolls:

Material: Cutting oil filter paper rolls are typically made from high-quality filter media that can effectively capture and retain solid particles, metal chips, swarf, and other contaminants commonly found in cutting fluids without breaking down when exposed to these fluids.

Filtration Efficiency: Filter paper rolls come in various grades, each offering different particle size retention capabilities. The choice of roll grade depends on the specific requirements of the machining process and the type of contaminants present.

Continuous Filtration: These rolls are often used in conjunction with industrial filtration systems, such as gravity bed filters, vacuum filters, or other custom filtration setups, to provide continuous and efficient filtration of cutting oils.

Compatibility: Cutting oil filter paper rolls are compatible with various types of cutting oils, coolants, and lubricants, including water-based and oil-based fluids.

Cost Savings: Proper filtration with these rolls can significantly reduce the frequency of cutting oil replacement, resulting in cost savings for industrial operations. It also helps extend the lifespan of expensive cutting tools and equipment.

Improved Machining Performance: Cleaner cutting fluids with reduced contamination levels can lead to improved machining performance, higher precision, and better surface finishes in metalworking processes.

Environmental Benefits: Effective filtration helps reduce waste and disposal costs associated with spent cutting oils and contributes to a more environmentally friendly manufacturing process.

Custom Sizing: Cutting oil filter paper rolls come in various widths and lengths to accommodate different filtration systems and industrial applications. They can be cut to size as needed.

Safety and Worker Health: Maintaining clean and uncontaminated cutting fluids promotes a safer working environment and reduces health risks for workers exposed to these fluids.

Preventative Maintenance: Regular replacement and maintenance of cutting oil filter paper rolls are crucial to ensure consistent filtration performance and prevent clogging, which can lead to equipment downtime.

In industrial metalworking and machining operations, using cutting oil filter paper rolls is essential for preserving the integrity of cutting fluids, protecting valuable machinery, and optimizing production processes. Effective filtration not only improves equipment performance but also has economic and environmental benefits.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Length | Upto 150 Meter |

| Color | White |

| White | Viscous, Thermal Bonded, Spoonless |

| Thickness | 0.12 to 10 mm |

| Application | For Filtration |

| Width | 350-1500 mm |

Grinding Coolant Filter Paper Rolls

Filters23 India are specialized filter materials used in industrial grinding applications to filter and purify the coolant or cutting fluid used during grinding processes. These filter rolls are designed to remove contaminants, particulates, swarf, and other debris from the coolant, helping to maintain the quality of the coolant and ensure the efficiency of the grinding equipment. Here are some key features and applications of grinding coolant filter paper rolls:

Material: Grinding coolant filter paper rolls are typically made from high-quality filter media capable of effectively capturing and retaining solid particles, metal fines, abrasive grit, and other contaminants found in grinding coolants without breaking down when exposed to these fluids.

Filtration Efficiency: Filter paper rolls are available in various grades, each offering different particle size retention capabilities. The choice of roll grade depends on the specific requirements of the grinding process and the type of contaminants present.

Continuous Filtration: These rolls are often used in conjunction with industrial filtration systems, such as gravity bed filters, vacuum filters, or other custom filtration setups, to provide continuous and efficient filtration of grinding coolants.

Compatibility: Grinding coolant filter paper rolls are compatible with various types of grinding coolants and cutting fluids, including water-based and oil-based fluids.

Cost Savings: Proper filtration with these rolls can significantly reduce the frequency of coolant replacement, resulting in cost savings for industrial grinding operations. It also helps extend the lifespan of expensive grinding wheels and equipment.

Improved Grinding Performance: Cleaner coolant with reduced contamination levels can lead to improved grinding performance, higher precision, and better surface finishes in metal grinding processes.

Environmental Benefits: Effective filtration helps reduce waste and disposal costs associated with spent grinding coolants and contributes to a more environmentally friendly manufacturing process.

Custom Sizing: Grinding coolant filter paper rolls come in various widths and lengths to accommodate different filtration systems and industrial applications. They can be cut to size as needed.

Safety and Worker Health: Maintaining clean and uncontaminated grinding coolants promotes a safer working environment and reduces health risks for workers exposed to these fluids.

Preventative Maintenance: Regular replacement and maintenance of grinding coolant filter paper rolls are crucial to ensure consistent filtration performance and prevent clogging, which can lead to equipment downtime.

In industrial grinding operations, using grinding coolant filter paper rolls is essential for preserving the quality of grinding coolants, protecting valuable machinery, and optimizing production processes. Effective filtration not only improves equipment performance but also has economic and environmental benefits.

| Business Type | Manufacturer, Supplier |

| Color | White |

| Condition | New |

| Country of Origin | India |

| Material | PP |

| Usage/Application | Industrial |

| GSM | 550 |

| Pattern | Plain |

Honing oil filter paper,

Honing oil filter paper, also known as filter media rolls or filter paper rolls for honing oil, is a specialized filter material used in the honing process to filter and purify honing oil or lubricants. The honing process involves finishing and smoothing the inner surfaces of cylindrical parts, such as engine cylinders or hydraulic cylinders, and honing oil is used as a lubricant and coolant during this process. Honing oil filter paper rolls play a crucial role in maintaining the quality of the honing oil and ensuring the efficiency of the honing equipment. Here are some key features and applications of honing oil filter paper rolls:

Material: Honing oil filter paper rolls are typically made from high-quality filter media designed to effectively capture and retain contaminants, metal fines, abrasive particles, and other debris found in honing oil without breaking down when exposed to these fluids.

Filtration Efficiency: Filter paper rolls come in various grades, each offering different particle size retention capabilities. The choice of roll grade depends on the specific requirements of the honing process and the type of contaminants present.

Continuous Filtration: These rolls are often used in conjunction with industrial filtration systems, such as gravity bed filters, vacuum filters, or other custom filtration setups, to provide continuous and efficient filtration of honing oil.

Compatibility: Honing oil filter paper rolls are compatible with various types of honing oils and lubricants, including water-based and oil-based fluids.

Cost Savings: Proper filtration with these rolls can significantly reduce the frequency of honing oil replacement, resulting in cost savings for industrial honing operations. It also helps extend the lifespan of expensive honing tools and equipment.

Improved Honing Performance: Cleaner honing oil with reduced contamination levels can lead to improved honing performance, higher precision, and better surface finishes on workpieces.

Environmental Benefits: Effective filtration helps reduce waste and disposal costs associated with spent honing oil and contributes to a more environmentally friendly manufacturing process.

Custom Sizing: Honing oil filter paper rolls come in various widths and lengths to accommodate different filtration systems and industrial applications. They can be cut to size as needed.

Safety and Worker Health: Maintaining clean and uncontaminated honing oil promotes a safer working environment and reduces health risks for workers exposed to these fluids.

Preventative Maintenance: Regular replacement and maintenance of honing oil filter paper rolls are crucial to ensure consistent filtration performance and prevent clogging, which can lead to equipment downtime.

In industrial honing operations, using honing oil filter paper rolls is essential for preserving the quality of honing oil, protecting valuable machinery, and optimizing production processes. Effective filtration not only improves equipment performance but also has economic and environmental benefits.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Filters23 India Pvt Ltd |

| Country of Origin | India |

| Type | Filter Roll,Sheets,Bags,Hot Oil Filter Paper |

| Pattern | Plain |

| Certification | ISO 9001:2008, CE Certified |

| Color | White |

| Material | Food Oil Filter Paper |

| Warranty | 1 year |

| Port | SANAD |

| Payment Terms | L/C, D/A |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | bundles , boxes |

Hot oil filter paper rolls are large rolls of filter paper designed specifically for use in commercial deep fryer filtration systems. They play a crucial role in maintaining the quality and longevity of frying oil in commercial kitchens, such as those in restaurants, establishments. Here are some key features and considerations related to hot oil filter paper rolls:

1. Heat Resistance: Hot oil filter paper rolls are made from materials that are heat-resistant and capable of withstanding the high temperatures of frying oil without breaking down or releasing harmful substances.

2. Continuous Filtration: These rolls are typically used in conjunction with commercial deep fryer filtration equipment that continuously filters hot cooking oil while the fryer is in operation.

3. Roll Format: Hot oil filter paper comes in a roll format, which allows for easy and efficient replacement when the existing filter paper becomes clogged with impurities.

4. Variety of Mesh Sizes: Filter paper rolls are available in various mesh sizes to accommodate different levels of filtration. The choice of mesh size can depend on the specific needs of the kitchen and the type of fried foods being prepared.

5. Compatibility: When selecting a hot oil filter paper roll, it's essential to ensure that it is compatible with the filtration equipment and fryer models used in the kitchen. Proper sizing and fit are crucial for effective filtration.

6. Efficient Filtration: Hot oil filter paper effectively captures impurities, food particles, and contaminants from the frying oil, helping to maintain oil quality and the taste of fried foods.

7. Cost Savings: By regularly filtering and maintaining cooking oil with the use of filter paper rolls, commercial kitchens can extend the life of their frying oil, reduce the frequency of oil replacement, and lower operational costs.

8. Improved Food Quality: Filtration with hot oil filter paper contributes to consistent and high-quality fried food products, as it removes debris and impurities that can negatively affect taste, texture, and appearance.

| Business Type | Manufacturer, Supplier |

| Condition | New |

| Country of Origin | India |

| Size | Length- 25,50,100 m |

| Thickness | 0.5 mm |

| Weight | 20 to 200 GSM |

| Color | White |

| Material Grade | 200 GSM |

| Material | Paper |

| Length | 100 m |

| Width | 400 mm |

Industrial Filter paper rolls

Polyester filter paper rolls are specialized filter media made from polyester fibres. These filter rolls are designed for various filtration applications, including air and liquid filtration. Polyester filter paper rolls offer several advantages, making them suitable for a range of industrial and commercial purposes:

Durability: Polyester filter paper is known for its durability and resistance to moisture and chemicals. It can withstand harsh operating conditions and is less prone to breaking down compared to some other filter materials.

High Filtration Efficiency: Polyester filter paper has excellent filtration efficiency, capturing a wide range of particles and contaminants, including dust, pollen, fine particulate matter, and more.

Low Resistance: Despite its high filtration efficiency, polyester filter paper typically has low airflow resistance. This allows for efficient filtration without significantly restricting the flow of air or liquid.

Versatility: Polyester filter paper is suitable for both air and liquid filtration applications. It can be used in HVAC systems, industrial dust collectors, automotive air filters, hydraulic filters, and more.

Customizable: Polyester filter paper rolls are available in various thicknesses and pore sizes to suit different filtration requirements. The choice of thickness and pore size can be tailored to the specific application.

Easy Maintenance: Installing or replacing polyester filter paper rolls is generally straightforward, making maintenance and filter changes relatively easy.

Chemical Resistance: Polyester fibers are resistant to many chemicals, which makes them suitable for applications where the filter media may come into contact with corrosive substances.

Cost-Effective: Polyester filter paper is often a cost-effective filtration solution due to its durability and long service life.

Environmentally Friendly: Using polyester filter paper can contribute to a reduction in filter waste and disposal costs, promoting environmental sustainability.

Common applications for polyester filter paper rolls include air filtration in HVAC systems, industrial dust collection, automotive engine air filters, hydraulic and lubrication oil filtration, and more. These rolls are valued for their ability to efficiently capture particles and contaminants while maintaining good airflow or liquid flow rates, making them a popular choice in many industries.

| Business Type | Manufacturer, Supplier |

| Color | White |

| Pattern | Plain |

| Material Grade | 40 GSM |

| Material | Paper |

| Length | 25 m |

| Width | 1000 mm |

| Thickness | 0.5 mm |

| Micron Ratings | 20 Micron |

Micron coolant filter paper rolls

Filters23 India`s Micron filter paper rolls, also known as filter media or filter paper rolls, are essential components in various filtration applications. They are used to capture and remove solid particles, contaminants, and impurities from liquids or gases. These rolls are designed to have specific filtration ratings, typically measured in microns, to ensure efficient filtration based on the particle size requirements of the application. Here's an overview of micron filter paper rolls:

Filtration Rating: The term "micron" refers to the size of particles that the filter can capture. A micron (µm) is equal to one-thousandth of a millimeter (0.001 mm). Micron filter paper rolls are available with different filtration ratings, which indicate the size of particles they can effectively capture. For example, a 10-micron filter can capture particles that are 10 micrometers or larger in size.

Material: Filter paper rolls can be made from various materials, including cellulose, synthetic fibers, glass fibers, and more. The choice of material depends on the compatibility with the filtered fluid or gas and the intended application.

Application: Micron filter paper rolls are used in a wide range of industries and applications, including:

Industrial Filtration: Used in manufacturing processes to remove contaminants and impurities from liquids or gases, such as in hydraulic systems, lubrication systems, and compressed air systems.

Laboratory and Healthcare: Utilized in laboratory settings for sample preparation, as well as in medical devices like blood filters.

Food and Beverage: Used to clarify liquids in food and beverage production, such as filtering fruit juices, oils, and wine.

Pharmaceuticals: Employed for sterile filtration of pharmaceutical products to ensure product quality and safety.

Automotive: Used in automotive filters, including oil filters and fuel filters, to remove contaminants and extend the life of engines.

Environmental Protection: Applied in wastewater treatment plants to remove solids from wastewater before discharge.

Roll Format: Filter paper rolls are typically supplied in continuous roll form, allowing them to be cut to the desired length to fit specific filtration equipment or housings. The rolls may have varying widths and lengths to accommodate different filter assemblies.

Filter Housing: Micron filter paper rolls are used within filter housings or assemblies that hold and secure the filter media. These housings ensure that the fluid or gas passes through the filter material, allowing contaminants to be captured while the clean fluid or gas continues downstream.

Replacement and Maintenance: Regular maintenance and replacement of filter paper rolls are essential to maintain filtration efficiency. The frequency of replacement depends on factors such as the application, contaminant load, and flow rate.

Performance: The performance of micron filter paper rolls is evaluated based on factors like filtration efficiency, flow rate, and pressure drop. Manufacturers often provide specifications to help users select the appropriate filter media for their specific needs.

When selecting micron filter paper rolls for a particular application, it's crucial to consider factors such as the desired filtration rating, compatibility with the fluid or gas, flow rate requirements, and the overall system design. Proper filtration is essential in various industries to ensure product quality, equipment reliability, and environmental protection.

| Business Type | Manufacturer, Supplier |

| Color | White |

| Pattern | Plain |

| Type | Paper Rolls |

| Country of Origin | Made In India |

| Material | Activated Carbon |

| Usage/Application | Water Filter |

| Length | 100m |

| Packaging Type | Roll |

| Thickness | 2mm |

Needle punch filter paper Roll

Needle-punch filter paper, also known as needle-punched filter paper or non-woven filter paper, is a type of filter media made by mechanically entangling or needling synthetic or natural fibers together to create a porous and filterable material. This needle-punching process enhances the strength, thickness, and filtration efficiency of the paper, making it suitable for various industrial and filtration applications. Here are some key features and applications of needle-punch filter paper:

Filtration Media: Needle-punch filter paper is designed to effectively capture and retain solid particles, contaminants, and impurities from liquids or gases. It is commonly used in various filtration systems to clarify and purify fluids.

Porosity: The needle-punching process creates a structure with controlled pore sizes, allowing for precise filtration based on the desired particle retention level.

Material: Needle-punch filter paper can be made from a wide range of materials, including synthetic fibers (polyester, polypropylene) or natural fibers (cellulose). The choice of material depends on the specific filtration requirements and the compatibility with the filtered medium.

Thickness: Needle-punched filter paper can be manufactured in various thicknesses to meet different filtration needs, from fine filtration to coarse filtration.

Strength and Durability: The mechanical entangling of fibers results in a strong and durable filter media that can withstand the rigors of filtration processes without tearing or collapsing.

Customizable: Manufacturers can customize needle-punch filter paper based on the desired pore size, thickness, and dimensions, making it suitable for a wide range of filtration applications.

Applications: Needle-punch filter paper is used in applications such as automotive oil filters, air filters for HVAC systems, water filtration systems, industrial dust collection, medical filtration, and more.

Cost-Effective: It is often a cost-effective filtration solution due to its durability and the ability to achieve precise filtration.

Ease of Installation: Needle-punch filter paper is typically easy to install or replace in various filtration systems, reducing maintenance downtime.

Environmental Benefits: Proper filtration with needle-punch filter paper can extend the life of equipment, reduce waste, and contribute to a more sustainable and environmentally friendly manufacturing process.

Needle-punch filter paper is a versatile filtration material that can be tailored to meet specific industrial and filtration needs. Its ability to provide efficient and reliable filtration makes it a valuable component in various filtration systems across different industries.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Oil Filter Paper |

| Certification | ISO 9001:2008, CE Certified |

| Application | Oil Filter |

| Color | White |

| Raw Material | Natural Fiber |

| Material | Paper |

| Brand Name | FILTERS23 India Pvt Ltd |

| Warranty | 1 year |

| Port | SANAD |

| Payment Terms | L/C, D/A |

| Delivery Time | 2-3 WEEKS |

| Packaging Details | bundles , rolls , sheets , boxes |

Oil filter paper rolls, also known as filter media rolls or filter paper rolls for oil filtration, are specialized filter materials used in various industrial and automotive applications to filter and purify oils. These filter rolls are designed to remove particulates, contaminants, debris, and impurities from oils, ensuring the cleanliness and quality of the oil and the efficient operation of machinery. Here are some key features and applications of oil filter paper rolls:

1. Material: Oil filter paper rolls are typically made from specialized filter media designed to effectively capture and retain solid particles, sludge, metal fines, and other contaminants found in oils without breaking down when exposed to these fluids.

2. Filtration Efficiency: Filter paper rolls come in various grades, each offering different particle size retention capabilities. The choice of roll grade depends on the specific requirements of the oil filtration process and the type of contaminants present.

3. Customizable: Manufacturers can customize oil filter paper rolls based on the desired pore size, thickness, and dimensions, making them suitable for a wide range of oil filtration applications.

4. Compatibility: Oil filter paper rolls are compatible with various types of oils, including engine oils, hydraulic oils, lubricating oils, transformer oils, and more.

5. Strength and Durability: The filter media in oil filter paper rolls is engineered to be strong and durable, capable of withstanding the pressure and flow rates typically encountered in oil filtration processes.

6. Cost Savings: Proper filtration with these rolls can significantly reduce the frequency of oil replacement, resulting in cost savings for industrial and automotive operations. It also helps extend the lifespan of valuable equipment and machinery.

7. Improved Oil Quality: Cleaner oil with reduced contamination levels can lead to improved equipment performance, reduced wear and tear, and longer oil life.

Oil filter paper rolls are commonly used in automotive oil filters, industrial hydraulic systems, transformer oil filtration, and various oil purification processes. They play a crucial role in ensuring the quality and longevity of oils, which is essential for the proper operation of engines, machinery, and equipment. Proper filtration with oil filter paper rolls also contributes to cost savings and environmental sustainability.