| Business Type | Manufacturer, Exporter |

| Application | Fryer Oil Filtration |

| Brand Name | Filters23 India Pvt Ltd |

| Material | Stainless Steel |

| Click to view more | |

Product Details

Filters23 India fryer oil filter machine, also known as a deep fryer oil filtration system, is a piece of equipment used in commercial kitchens, particularly in restaurants and foodservice establishments, to extend the lifespan of cooking oil used in deep fryers. These machines are designed to filter and clean frying oil, removing impurities, food particles, and contaminants to maintain the quality of the oil, reduce waste, and improve the taste and texture of fried foods. Here's how a fryer oil filter machine typically works and its key features:

How a Fryer Oil Filter Machine Works:

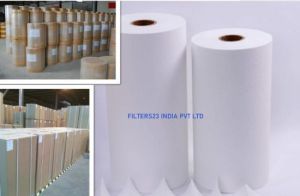

1. Filtration System: The machine is equipped with a filtration system that can include various components like a filter pump, filter housing, filter media (usually a disposable or reusable filter paper), and sometimes a separate holding tank for the used oil.

2. Hot Oil Handling: Fryer oil filter machines are designed to handle hot oil. They can be used while the oil is still hot, allowing for continuous frying operations.

3. Filtering Process: The oil from the deep fryer is pumped or drained into the filtration system, where it passes through the filter media. The filter media captures impurities, food particles, and other contaminants present in the oil.

4. Cleaned Oil Return: The filtered and cleaned oil is then pumped or returned to the fryer for reuse. This process improves the quality and clarity of the oil, resulting in better-tasting and more visually appealing fried foods.

5. Waste Collection: Any solid debris or contaminants captured by the filter media are typically collected in a waste container for easy disposal.

Key Features of Fryer Oil Filter Machines:

1. Various Sizes: Fryer oil filter machines come in various sizes and capacities to suit the needs of different commercial kitchens, from small restaurants to large food production facilities.

2. Portability: Many models are designed to be portable, allowing easy movement between fryers and making them suitable for use with multiple fryers.

3. Quick Filtration: These machines are designed for quick and efficient filtration, minimizing downtime during the cooking process.

4. Temperature Control: They can handle hot oil, often allowing for continuous filtering without the need to cool down the oil.

5. User-Friendly Controls: Most machines have user-friendly controls for easy operation.

6. Safety Features: They may include safety features to prevent spills and accidents, such as splash guards or locking mechanisms.

7. Extended Oil Life: Regular use of a fryer oil filter machine can significantly extend the lifespan of frying oil, reducing the frequency of oil changes and associated costs.

8. Improved Food Quality: Cleaner oil results in better-tasting and more visually appealing fried foods.

Fryer oil filter machines are essential in commercial kitchens where deep frying is a common cooking method. They help maintain the quality of cooking oil, reduce waste, and improve the consistency and taste of fried foods. The choice of a specific machine depends on the size of the fryer, the volume of frying done, and the filtration needs of the kitchen. Properly maintained oil can lead to cost savings and higher customer satisfaction.

Looking for "S.s Fryer Oil Filter System" ?

Explore More Products