| Business Type | Manufacturer, Supplier |

| Phase | Three Phase |

| Power Source | Electric |

| Voltage | 220 V |

| Click to view more | |

Product Details

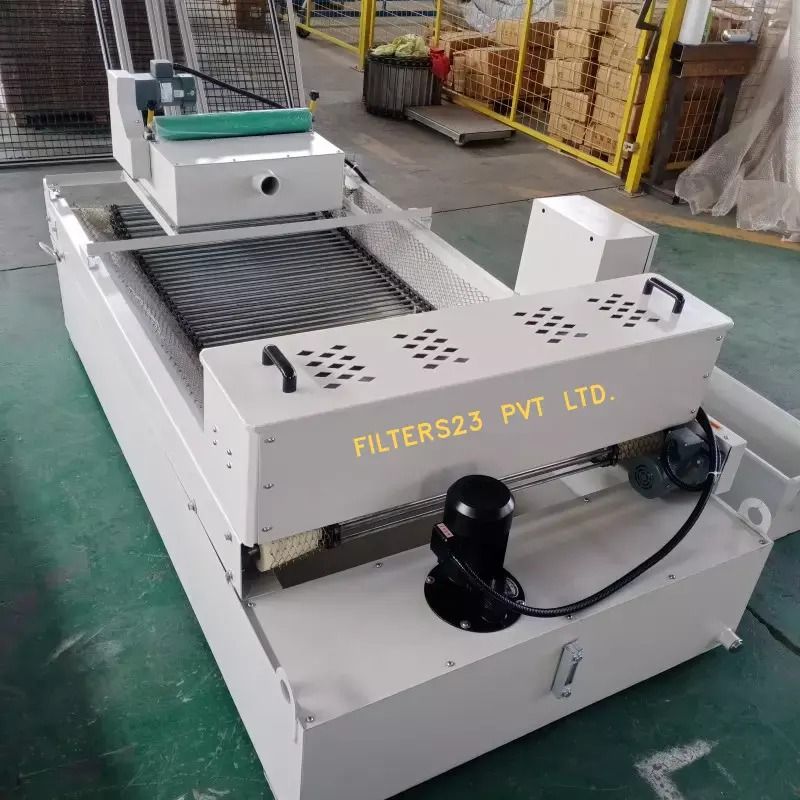

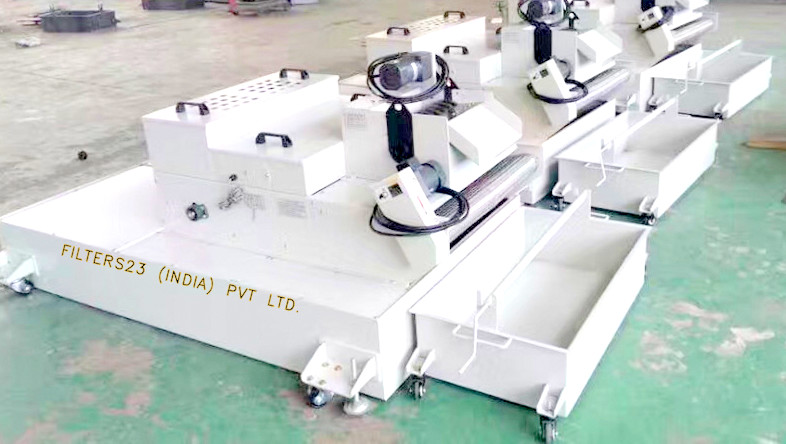

Paper Band Cum Magnetic Separator

FILTERS23 INDIA`S paper band cum magnetic separator is a machine or device used in industrial settings to separate ferrous (iron-containing) particles from other materials, typically in a manufacturing or recycling process. This type of equipment combines two separate functions: paper band filtration and magnetic separation.

Paper Band Filtration: A paper band filtration system is used to filter out solid particles from a liquid or coolant. In industrial processes like metal machining or grinding, a coolant is often used to cool the cutting tools and remove debris. As the coolant circulates, it can become contaminated with metal shavings and other solid particles. The paper band filtration system uses a continuous loop of filter paper or a similar material to trap and remove these contaminants from the coolant, allowing the clean coolant to be reused.

Magnetic Separation: Magnetic separation is a method used to separate magnetic materials (such as iron and steel) from non-magnetic materials. In this process, a magnetic field is applied to a mixture of materials, causing the magnetic particles to be attracted to a magnetic surface or separator, while non-magnetic materials remain unaffected.

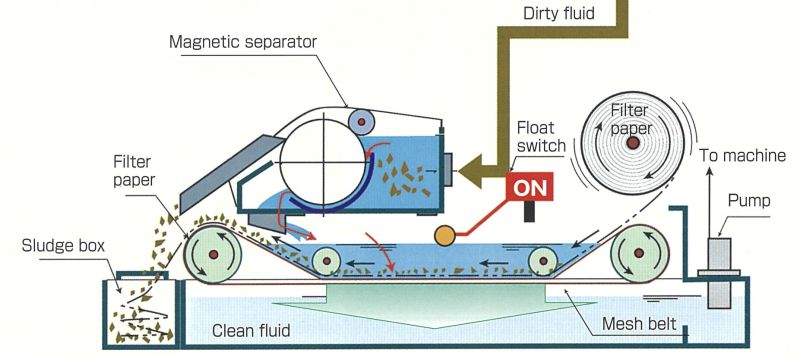

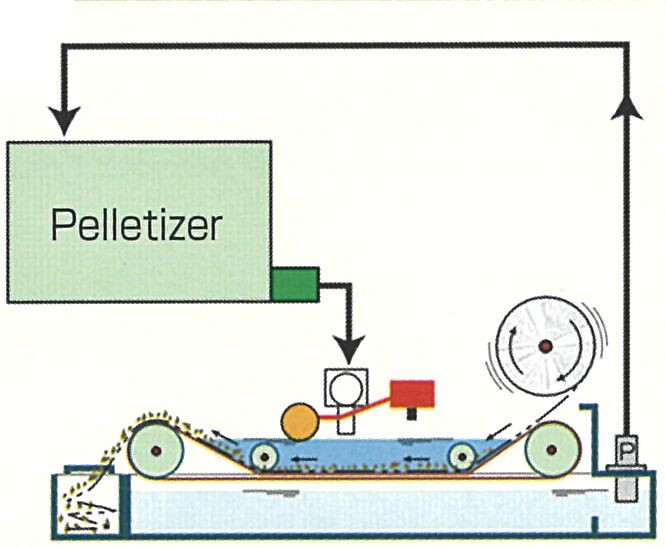

A paper band cum magnetic separator combines these two processes into a single machine. Here's how it typically works:

The contaminated coolant or liquid containing both solid particles and magnetic materials is fed into the system.

The paper band filtration system filters out the solid particles (including non-magnetic materials) from the liquid, as it passes through the filter paper.

Simultaneously, a magnetic separator within the machine uses a magnetic field to attract and separate the ferrous or magnetic particles from the remaining liquid.

The separated magnetic particles are collected in a separate container or bin, while the clean liquid is returned to the industrial process for reuse.

This type of equipment is commonly used in industries like metalworking, automotive manufacturing, and recycling where the separation of ferrous contaminants from liquids is essential for maintaining the quality of products and extending the life of cutting tools and equipment.

The specific design and operation of a paper band cum magnetic separator can vary depending on the manufacturer and the requirements of the industrial process it serves.

Looking for "Automatic Paper Band Cum Magnetic Separator" ?

Explore More Products