| Business Type | Manufacturer, Supplier |

| Color | White |

| Condition | New |

| Country of Origin | India |

| Click to view more | |

Product Details

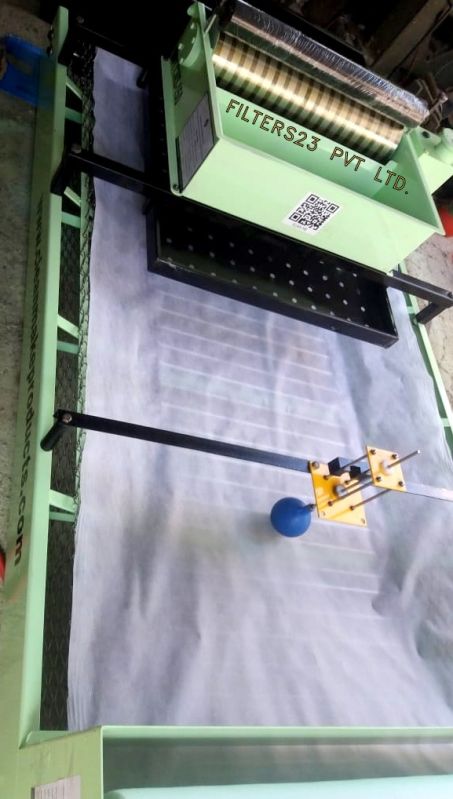

Paper band filter paper rolls

Filters23 India’s Paper band filter paper rolls, also known as filter media or filter paper rolls, are specialized filter materials used in paper band or paper belt filtration systems. These systems are commonly used in industrial applications, particularly in metalworking and machining processes, to filter out solid particles and contaminants from cutting fluids or coolants used during machining operations. Here's an overview of paper band filter paper rolls and their applications:

1. Filtration in Metalworking and Machining:

Metalworking Fluids: Paper band filtration is widely used in metalworking applications such as grinding, milling, turning, and honing, where metal chips and debris can contaminate cutting fluids or coolants.

Coolant Filtration: The primary purpose of paper band filter paper rolls is to capture and remove solid particles, metal fines, and other contaminants from the coolant, thus extending the life of the coolant and improving machining efficiency.

2. Filter Media Characteristics:

Filtration Rating: Paper band filter paper rolls are available in various filtration ratings measured in microns. The choice of filtration rating depends on the application and the desired level of filtration.

Material: These rolls are typically made from specialized filter paper or fabric materials that offer high particle retention capabilities and are compatible with the cutting fluids or coolants used in machining processes.

3. Roll Format:

Paper band filter paper rolls come in a continuous roll format, allowing users to cut the material to the required length to fit their specific filtration equipment. The rolls may have varying widths and lengths to accommodate different filter systems.

4. Operation:

In a paper band filtration system, the filter paper roll is positioned within a filtration unit, often shaped like a cylindrical drum or belt. The cutting fluid or coolant flows through the filter media as it circulates through the machining process.

As the fluid passes through the filter paper roll, solid particles and contaminants are trapped by the filter media, effectively cleaning the fluid.

Periodically, the filter paper roll may need to be advanced or replaced when it becomes saturated with contaminants. This can be done manually or automatically, depending on the system design.

5. Benefits:

Improved Machining Performance: Paper band filtration helps maintain the cleanliness of cutting fluids, which enhances tool life, surface finish, and overall machining quality.

Cost Savings: By extending the life of cutting fluids, paper band filtration reduces the need for frequent fluid replacement and disposal, resulting in cost savings.

Environmental Impact: Reducing the disposal of contaminated cutting fluids is environmentally responsible and compliant with environmental regulations.

6. Maintenance and Replacement:

Regular maintenance and replacement of the filter paper roll are necessary to maintain filtration efficiency and prevent the buildup of contaminants in the machining process.

Looking for "Band Filter Paper Roll" ?

Explore More Products