| Business Type | Manufacturer, Supplier |

| Material | Stainless Steel |

| Country of Origin | India |

| Condition | New |

| Click to view more | |

Product Details

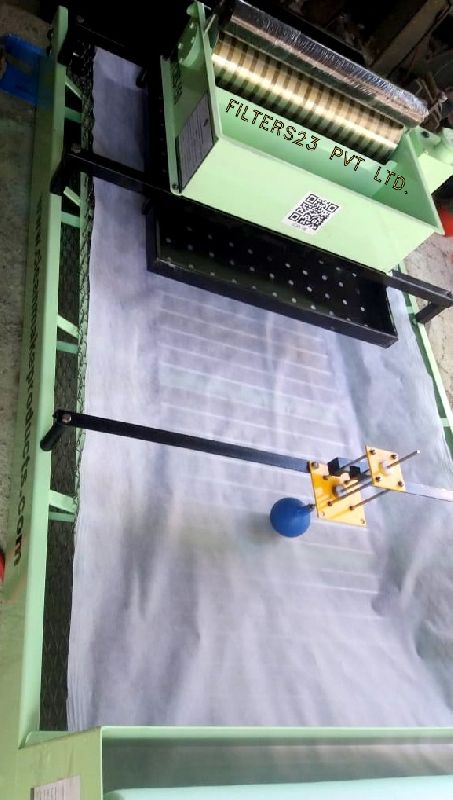

Gravity Band Filter

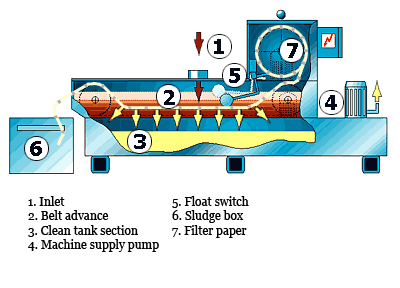

Gravity band filter is an industrial filtration system designed to remove solid particles and contaminants from a liquid using the force of gravity. It is a passive filtration method that relies on the principle of gravity to separate solids from liquids. Gravity band filters are commonly used in various manufacturing processes, especially in applications where a continuous and automatic filtration system is required. Here's how a typical gravity band filter works:

Inlet: Contaminated liquid, such as coolant or wastewater, is fed into the gravity band filter system through an inlet.

Distribution Mechanism: The incoming liquid is evenly distributed over a wide, flat surface, typically made of a porous material like a filter cloth or filter media. This distribution mechanism ensures that the liquid spreads uniformly across the filter surface.

Gravity Filtration: Gravity plays a crucial role in the filtration process. As the liquid flows over the filter surface under the influence of gravity, solid particles and contaminants are separated from the liquid and are trapped on the surface of the filter media.

Solid Accumulation: Over time, as more and more solid particles are captured, they form a layer or cake on the surface of the filter media. This layer acts as an additional filtration barrier, helping to improve the efficiency of the filter.

Clean Liquid Collection: The filtered liquid, now free of solid contaminants, flows through the filter media and is collected in a reservoir or trough beneath the filter surface.

Continuous Operation: Gravity band filters are designed to operate continuously. As long as the incoming liquid contains contaminants, the filtration process continues, and the solid particles continue to accumulate on the filter media.

Periodic Maintenance: Eventually, the filter media becomes clogged with a significant amount of solid material. At this point, the filter may need to be stopped for maintenance. The solid cake is removed from the filter media, often using a scraper or other mechanical means. After cleaning, the filter can resume operation.

Gravity band filters offer several advantages:

Continuous Operation: They can operate continuously without the need for frequent replacement of filter media.

Low Energy Consumption: These filters typically require minimal energy to operate since they rely on gravity.

Effective Filtration: They are effective at removing solid particles from liquids and are suitable for various industrial applications.

Low Maintenance: While they do require periodic maintenance to remove the accumulated solids, this is usually less frequent compared to other filtration methods.

Gravity band filters are commonly used in industries such as wastewater treatment, food processing, chemical manufacturing, and mining. The choice of filter media and the design of the system can be tailored to specific application requirements, including particle size, flow rates, and filtration efficiency.

Looking for "Gravity Band Filter" ?

Explore More Products